Hyundai Motor Co. is set to establish its first electric vehicle (EV) battery production lines by 2027, aiming to internalize battery technology and enhance EV performance and cost competitiveness, according to sources familiar with the plan.

The South Korean automaker is expected to build production lines with a capacity of 1-2 GWh at a research and development center in Anseong, Gyeonggi Province, producing prototype battery products independent of its current battery suppliers.

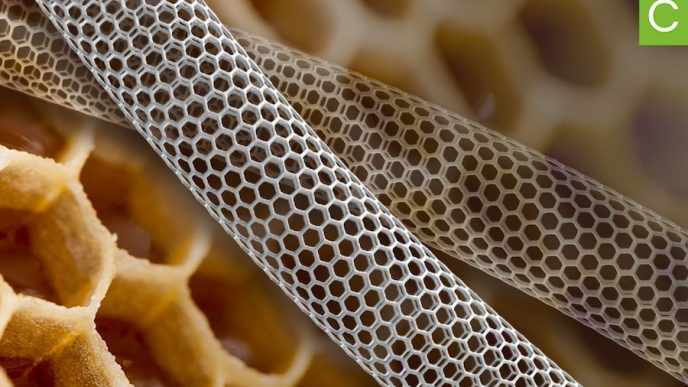

Hyundai has reportedly been negotiating with cathode material suppliers such as L&F Co., LG Chem Ltd., and Chinese companies to procure materials for these prototype batteries, with shipments expected to begin in 2027. The automaker is also considering producing ternary batteries, such as nickel-cobalt-manganese (NCM) batteries, which are known for their higher energy density and performance.

The company may also partner with battery cell makers like SK On to outsource production under original equipment manufacturing contracts. This move would enable Hyundai to create tailor-made batteries for its EVs, enhancing production efficiency and competitiveness.

Hyundai, Kia Corp., and Genesis EVs currently use pouch-type NCM or NCMA batteries from suppliers SK On and LG Energy Solution, while budget models like the Kona, Niro, and Ray use lithium iron phosphate (LFP) batteries from China’s CATL.

Hyundai’s push to internalize battery production aligns with broader industry trends, as batteries account for roughly 40% of an EV’s production cost and significantly impact vehicle performance. Other automakers, including Tesla, BYD, General Motors, and Toyota, have also taken steps to internalize battery technology. Despite Hyundai’s plans, the company is not expected to reduce the volume of batteries it purchases from existing suppliers.

Source: kedglobal.com