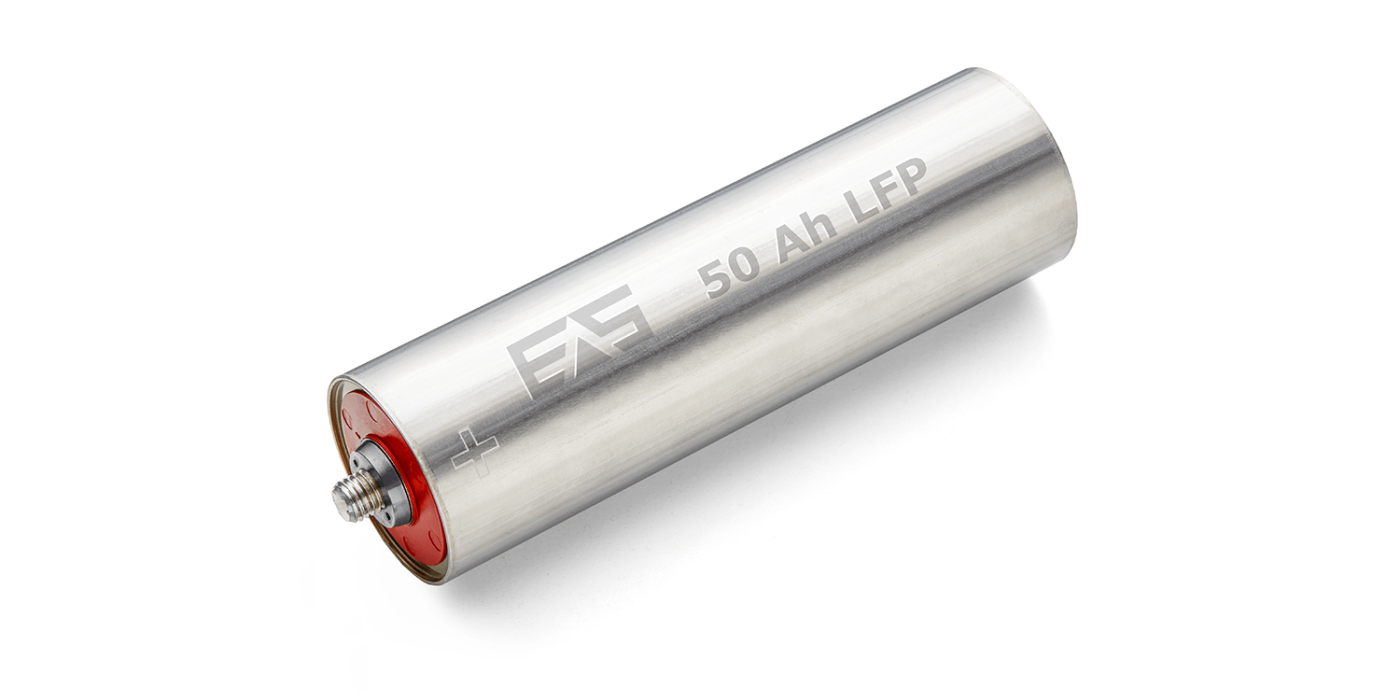

The DiLiRec project, a novel recycling initiative led by researchers from nine institutions and companies, is pioneering processes for the recovery of lithium iron phosphate (LFP) batteries for the first time. Coordinated by EAS Batteries in Thuringia, Germany, the project is set to transform the recycling landscape.

Over the next three years, the DiLiRec research network will focus on sorting, dismantling, and stripping LFP batteries to enable efficient recycling. Automated and digitalized processes will support the separation of the active mass, with a focus on large-format round cells from EAS Batteries, which offer high recycling potential due to their design allowing for complete unwinding and component separation.

See also: BorgWarner Forges Alliance with FinDreams Battery for LFP Battery Pack Localization

Two methods for recovering LFP cathode material from cylindrical cells are being explored: direct recycling, where LFP is fully recovered as active material, and standard recycling, which isolates precursors of LFP synthesis for use as secondary raw materials.

The project partners are developing and comparing two process routes for each method, employing wet-mechanical and dry-mechanical decoating processes for the electrodes. The systematic recording of material and process data, aided by artificial intelligence, aims to create conditions for sustainable and cost-effective LFP recycling.

See also: CATL and Stellantis Forge Partnership for LFP Battery Gigafactory in Europe

Partners in the DiLiRec project include EDI GmbH, BLC – The Battery Lifecycle Company GmbH, FNE Entsorgungsdienste Freiberg GmbH, the Fraunhofer Institute for Ceramic Technologies and Systems IKTS, Omron Electronics GmbH, TU Bergakademie Freiberg, IBU-tec advanced materials AG, and Reelements GmbH. The project, with a total volume of 4.7 million euros, receives around 2.7 million euros in funding from the German government.

Michael Deutmeyer, Managing Director of EAS Batteries, highlights the importance of sustainable battery recycling for the growth of electromobility and meeting EU Battery Regulation requirements.

Sebastian Hippmann, a research associate at Fraunhofer IKTS, notes the potential for less complex and energy-intensive methods to recover lithium from LFP compared to other battery chemistries like NCM and NCA, making direct recycling of LFP promising due to its material properties.

Successful recycling of LFP batteries could reduce raw material and product dependencies, strengthening Germany’s production capabilities and improving raw material efficiency. Collaboration between battery makers and recycling businesses is crucial for maximizing the productivity of the battery value chain.