Research Fabrication Battery Cell FFB, based in Münster, is making significant strides in its fourth sub-project, spearheaded by RWTH Aachen University, with a primary focus on advancing solid-state batteries. This initiative aims to address fundamental questions surrounding the production of these batteries, marking a pivotal moment in the evolution of battery cell technology.

Since its inception in 2021, the Research Production Battery Cell FFB, a Fraunhofer institution, has been steadfastly committed to expediting innovation and commercialization processes for production technologies catering to both existing and future cell formats. With three existing sub-projects under its belt, the institution has already made significant progress. The completion of the first sub-project, focusing on the development and deployment of a production line, underscores FFB’s dedication to driving technological advancements in battery cell production.

The subsequent sub-projects have delved into the development of electrode and cell designs for prismatic and pouch cells (FoFeBat2), as well as an accelerated forming procedure and optimized end-of-line testing (FoFeBat3).

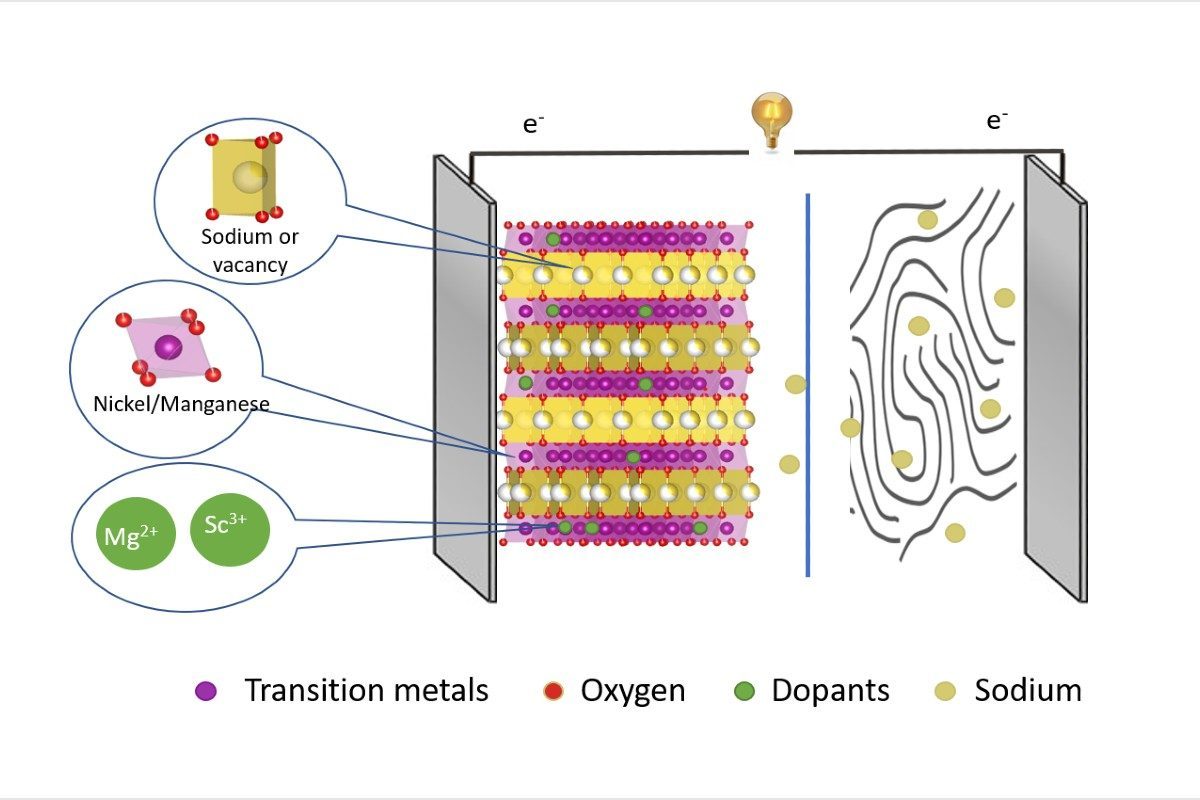

In its latest endeavor, dubbed ‘FoFeBat4’, FFB has expanded its consortium to include various scientific institutions, intensifying research efforts into solid-state batteries. Professor Achim Kampker, head of PEM, underscores the complexity of solid electrolyte systems, emphasizing the challenges in establishing a clear frontrunner among oxide, thiophosphate, and polymer systems. “The high demands on the production environment and the sometimes significant differences in the manufacturing processes, equipment, and materials required make it very difficult to adapt a production process chain for conventional lithium-ion batteries to the manufacture of solid-state batteries,” comments Kampker.

Nevertheless, Kampker acknowledges the widespread industry consensus regarding the transformative potential of solid-state batteries, which could facilitate the utilization of lithium-metal-based anodes, ultimately achieving heightened energy density. Major automotive and battery cell manufacturers worldwide have already invested substantially in solid-state battery research and development, forging strategic alliances with specialized companies.

The primary objective of FFB’s fourth sub-project is to unravel the complexities surrounding solid-state battery production while concurrently establishing essential infrastructure. Synthesizing existing electrolyte systems on a large scale and subjecting them to rigorous examination across various cell chemistries for performance, operational conditions, and safety aspects represents one of the key approaches outlined in an accompanying press release.

By bridging the gap between science and industry, FFB endeavors to enhance production technologies for current and future cell formats. Research and test projects of diverse scopes are envisioned, with both large industrial enterprises and small to medium-sized enterprises poised to reap the benefits.

Amid initial uncertainties stemming from budget cuts at the turn of the year, Germany’s commitment to battery research remained steadfast. While budget allocations were indeed reduced, they were not as severe as initially anticipated, ensuring continued support for critical research initiatives.

Recalling the genesis of battery cell research production, a consortium led by the Fraunhofer IPT secured the mandate following a rigorous application process in 2019. Collaborating with other Fraunhofer institutes, PEM of RWTH Aachen University, and the MEET Battery Research Centre, FFB was established in Münster. Despite initial challenges and criticisms, the center commenced its research activities in August 2021, poised to drive innovation in battery cell production and solidify Germany’s position as a frontrunner in battery technology.