Factorial Energy, a solid-state battery developer, has announced a strategic collaboration with Young Poong, a South Korean metal refining company, to explore and implement lithium-metal recycling in its production processes. By harnessing the potential of recycling excess metal materials, Factorial aims to contribute to the establishment of a more sustainable and circular economy.

Headquartered in Massachusetts, Factorial Energy has been at the forefront of developing cutting-edge technology to support electric vehicle (EV) applications. The company has formed significant joint ventures with renowned automotive leaders, including Mercedes-Benz, Hyundai Motor Group, and Stellantis.

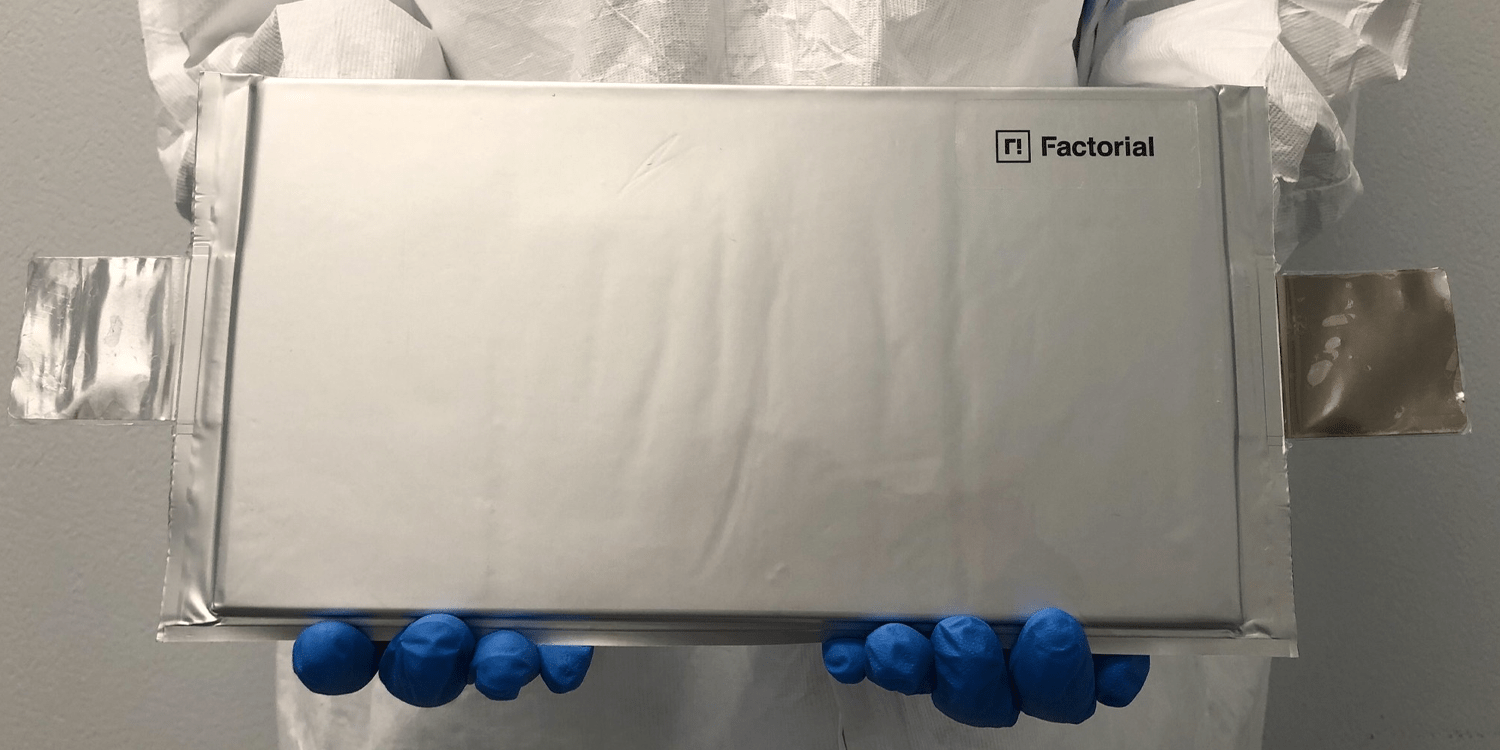

The flagship product of Factorial Energy is its Factorial Electrolyte System Technology (FEST), a proprietary approach that utilizes solid electrolyte material. At the Consumer Electronics Show (CES) held earlier this year, the company unveiled a prototype of its 100 Amp-hour (Ah) solid-state cell. Notably, this cell is compatible with existing lithium-ion battery manufacturing equipment, facilitating a smoother transition for automakers to adopt advanced battery cells.

See also: Factorial, EV solid-state battery manufacturer announces operations in Japan

In a significant milestone, Factorial Energy announced in May that it had obtained certification to ship its 100 Ah solid-state cells to automakers for testing. This move allows manufacturers to evaluate the cells’ performance firsthand and consider their integration into forthcoming electric vehicle models.

As Factorial Energy works towards scaling up solid-state battery production, with the potential to revolutionize an already thriving EV industry, the company is committed to optimizing its production practices through the recycling of valuable lithium metal residue generated during the manufacturing process. To achieve this, Factorial Energy has enlisted the expertise of Young Poong, marking the refining company’s first foray into solid-state recycling.

Today, Factorial Energy announced its latest partnership with Young Poong, wherein it will supply the South Korean metal smelting and refining company with excess lithium-metal material generated during the production of FEST solid-state batteries. Young Poong intends to leverage this lithium material to develop a recycling process that enables its integration into additional solid-state batteries, fostering a circular economy. If successful, this collaboration would mark an industry-first achievement in promoting sustainable recycling within the burgeoning solid-state segment.

One crucial aspect that sets the lithium-metal anodes used in Factorial’s solid-state batteries apart is the need for a distinct recycling process compared to the traditional lithium-ion cells found in current EVs. Cofounder and CTO of Factorial Energy, Alex Yu, emphasized the significance of this partnership, stating:

“Our core mission to advance sustainable mobility extends beyond EV battery manufacturing. We are deeply invested in advancing technologies that foster a circular economy. Through our partnership with Young Poong, Factorial is poised to shape a future characterized by a resilient supply chain for solid-state batteries, thereby helping to drive the growth and sustainability of the EV industry.”

See also: Factorial Energy Expands Presence in Europe with Solid-State Battery Technology for EVs

Young Poong, renowned for its battery recycling expertise, describes its current recycling technique as the world’s first pyrometallurgy process, boasting impressive recovery rates of over 90% for lithium, and more than 95% for nickel, cobalt, and copper from used batteries. In collaboration with Factorial Energy, the company has pledged to invest in the development of a project to adapt a similar recycling process specifically for solid-state batteries. Kang In Lee, a representative from Young Poong’s business division and green metal division, expressed their enthusiasm:

“We are pleased to be working with Factorial to advance our research into lithium-metal recycling for solid-state rechargeable batteries, an industry first. With lithium-metal recycling, we have the opportunity to establish a recycling process well in advance of the future decommissioning of solid-state batteries.”

Initially, Factorial Energy will provide Young Poong with surplus materials from its ongoing solid-state pilot manufacturing process. Additionally, Young Poong will be present at Factorial’s future production facilities as the company strives to scale up its FEST cells towards full commercialization.