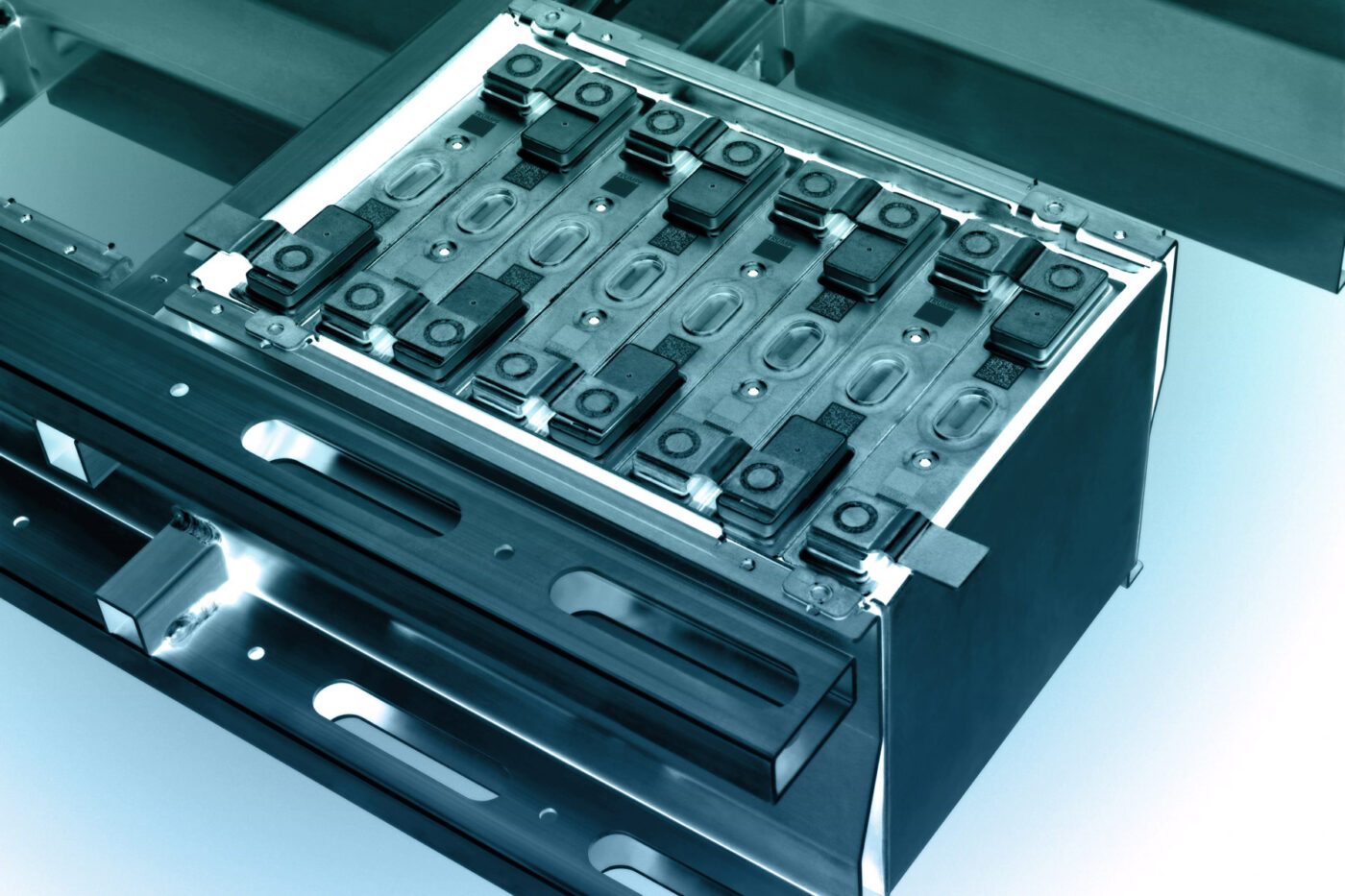

A European research project, DigiCell, has been launched to enhance the efficiency, reliability, and sustainability of electric vehicle (EV) battery production by integrating digital processes and data-driven analysis.

The 13-member DigiCell project, initiated this week in Vienna, Austria, aims to improve battery cell and battery pack manufacturing and testing processes using digital tools and artificial intelligence (AI). The project will not only focus on lithium-ion batteries (LiB) but also explore “innovative cell solutions beyond lithium,” according to project researchers.

See also: Tozero and Huayou Recycling Forge Partnership for Battery Waste Management in Europe

Dr. Nawfal Al-Zubaidi-R Smith, deputy coordinator of the project at Keysight Technologies, stated, “We will combine advanced battery and materials tests with multi-physics modeling and integrate them into an open-environment ecosystem.” This approach aims to “revolutionize” the EU scientific landscape for batteries, supported by AI-based data analytics, he added.

The research will involve developing new measuring tools for materials and creating multi-scale, digitally integrated battery models using machine learning. These efforts seek to reduce production costs, material usage, and the CO2 footprint in production lines while improving the electrochemical performance of battery cells.

See also: Li-Cycle Unveils First European Battery Recycling Plant in Magdeburg

Apart from project coordinator Keysight Technologies and the AIT Austrian Institute of Technology, the project involves Roma Tre University, Johannes Kepler University Linz, Politecnico di Torino, Leitat Technological Center, University of Picardy Jules Verne, Centre National de la Recherche Scientifique, Innovation in Research & Engineering Solutions, International Standards Consulting, Kreisel Electric, Centro Ricerche Fiat, the Swiss Federal Institute of Metrology, and the European Research and Project Office.

The AIT Austrian Institute of Technology will investigate the formation, evolution, and degradation mechanism of the solid electrolyte interface layer (SEI) on Mg|Mg symmetric cells using innovative characterization methods. It will also focus on the development of a single-layer Mg-ion pouch cell prototype and research recycling and second-life applications for Li-ion cells.

See also: Gotion High-tech’s First European Battery Plant in Germany Begins Production

Martina Romio, AIT project manager for DigiCell, emphasized, “As part of DigiCell, we want to make a significant contribution to sustainable, resource-conserving, and cost-efficient battery cell production in Europe – in line with the objectives of the European Green Deal.”