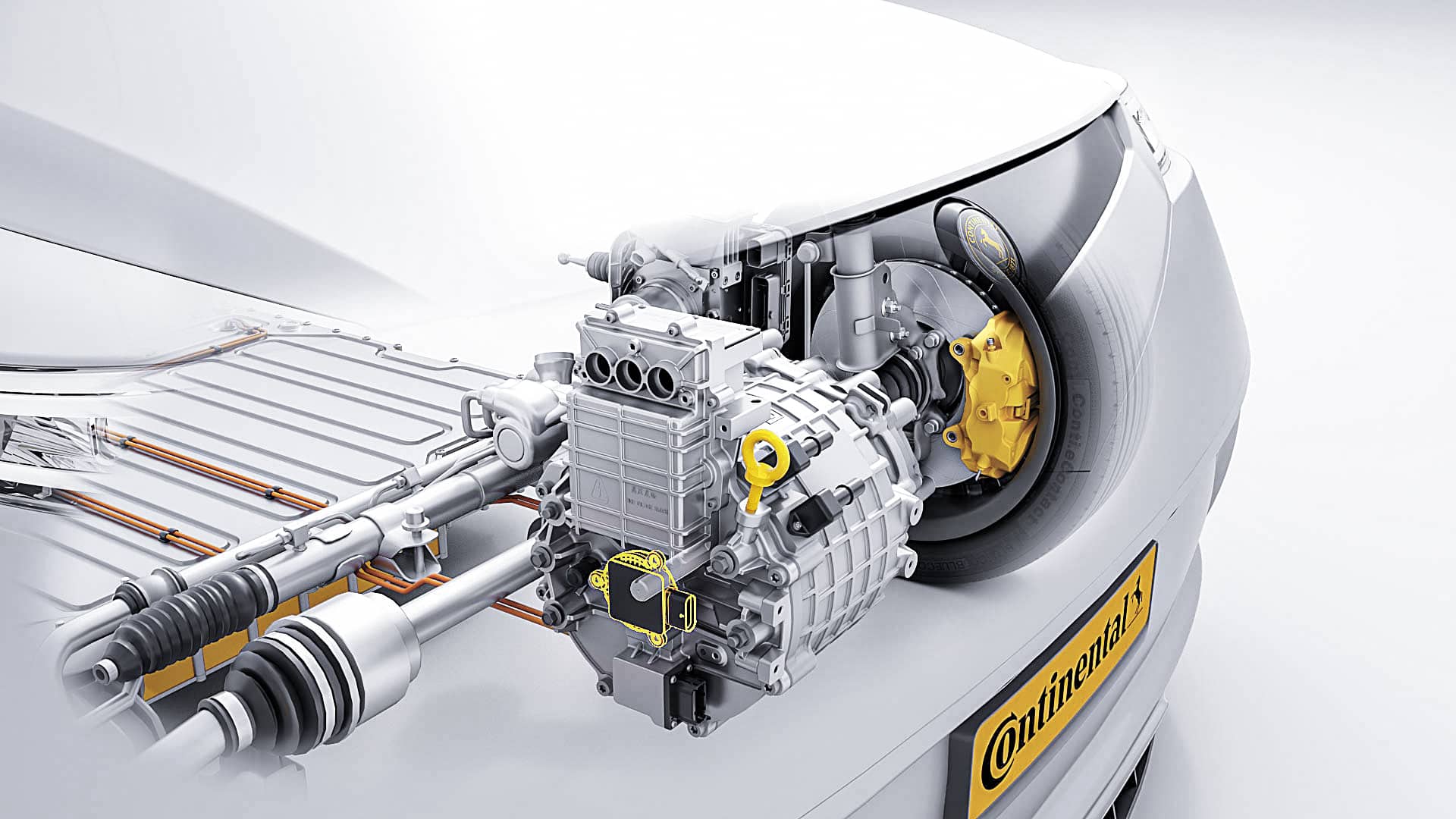

German multinational company, Continental, has announced the development of a new sensor that will help to improve the efficiency and performance of electric cars. The e-motor Rotor Position Sensor (eRPS) will be added to the company’s sensor portfolio for the fast-growing electric car market. With the start of production planned for the end of 2025, the eRPS is expected to enhance the driving experience of electric cars by offering improved accuracy, efficiency and smoother operations.

The eRPS sensor is designed to detect the exact position of the rotor in a synchronous electric machine. By doing so, it can help to increase efficiency and enable smoother operations. It is more compact and 40% lighter in weight than existing resolver sensors. With a maximum current consumption of 15mA, the eRPS offers an electrical accuracy of ±0,5° for a four-pole pairs motor. It is optimised to cover rotational speed requirements needed for future electric vehicle platforms (~24,000 rpm). The sensor’s operating temperature range is very wide and falls between -40 °C to 140 °C and peaks up to 155 °C.

See also: Continental and Ambarella Partner to Develop Self-Driving Vehicle Software and Hardware Systems

The eRPS sensor is an essential component for synchronous motor applications, as it provides the motor control unit with the exact position of the rotor. This information is vital for achieving maximum motor efficiency. The sensor design is based on the eddy current principle, and state-of-the-art integrated circuits (ICs) are used for signal processing. The IC has been designed according to ISO 26262 functional safety automotive standards to reach ASIL C. Additionally, two ICs can be embedded in the eRPS to ensure redundancy, which is an integral part of functional safety.

The eRPS sensor can be mounted through the shaft or integrated at the end of the rotor shaft, including the sealing function. The module contains excitation and reception coils embedding one or two ICs that directly detect the electrical angular position of the metallic encoder on the rotor shaft.

See also: Continental reveals Green Caliper, lightweight brake design for electric vehicles

Laurent Fabre, Head of Passive Safety and Sensorics Segment at Continental, commented on the sensor’s potential impact, noting that the growth in vehicle electrification translates into more synchronous motors in the car. With the eRPS, Continental aims to support the increasing demand for high-performance electric vehicles by providing an innovative sensor that can help improve efficiency, performance and the overall driving experience. The start of production of the eRPS is planned for the end of 2025.