Italian automation specialist Comau, a member of the Stellantis Group, is making significant strides in the field of sustainable battery recycling and second-life reuse with its participation in the EU’s Flex-BD project. This initiative aims to develop a fully automated system for dismantling used electric vehicle (EV) batteries, ensuring a highly efficient and standardized process.

Flex-BD, short for “Flexible Battery Dismantling,” is a robotic system designed by Comau to automate the entire dismantling process of EV batteries. By leveraging its expertise in automation, Comau has created a solution that offers flexibility, repeatability, and standardization. The system reduces the reliance on manual labor, with robots taking over repetitive and physically demanding tasks, as well as handling potentially hazardous substances. As a result, the recovery of battery modules and their components becomes more efficient and cost-effective.

After successfully validating the proof-of-concept in the initial phase of the project, Comau has expanded the scope of Flex-BD to include second-life recycling of car batteries. This extension aims to significantly enhance the previously labor-intensive processes involved in battery disassembly. The automated handling of modules in second-life storage facilities provides a substantial safety advantage. In recycling scenarios, batteries are discharged completely, reducing risks for operators and equipment. However, modules destined for second-life storage retain a low state of charge, which poses a potential risk of short circuits or other discharges.

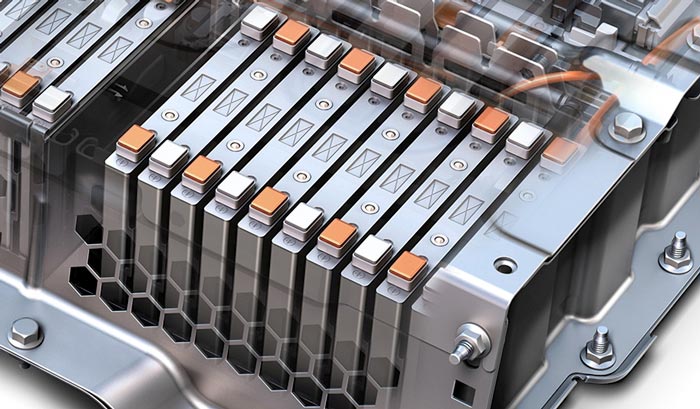

The key component of the Flex-BD system is a Comau NJ series industrial robot known as the “Flex-BD cell.” In a typical recycling application, the robot performs various tasks such as unscrewing the battery cover, changing grippers to remove the cover, unscrewing the modules using a screwdriver, and transporting the pieces to a dedicated storage area using its gripper. This automated process streamlines operations and ensures a seamless workflow.

Pietro Gorlier, CEO of Comau, emphasizes the company’s commitment to leveraging its expertise in automation to develop flexible, scalable, and sustainable processes through the Flex-BD project. By expanding their smart automation solution to encompass second-life repurposing of high-power batteries, many of which still retain up to 80% residual capacity, Comau is making a tangible contribution to the realization of truly sustainable mobility.

The advancements achieved by Comau in the field of battery recycling and second-life reuse represent a significant step forward in addressing the environmental challenges posed by EV batteries. With the deployment of automated systems like Flex-BD, the industry can effectively manage the lifecycle of these batteries, ensuring their safe and sustainable disposal or repurposing. As the world continues to transition towards a greener future, innovative solutions like Flex-BD play a crucial role in driving sustainable mobility forward.