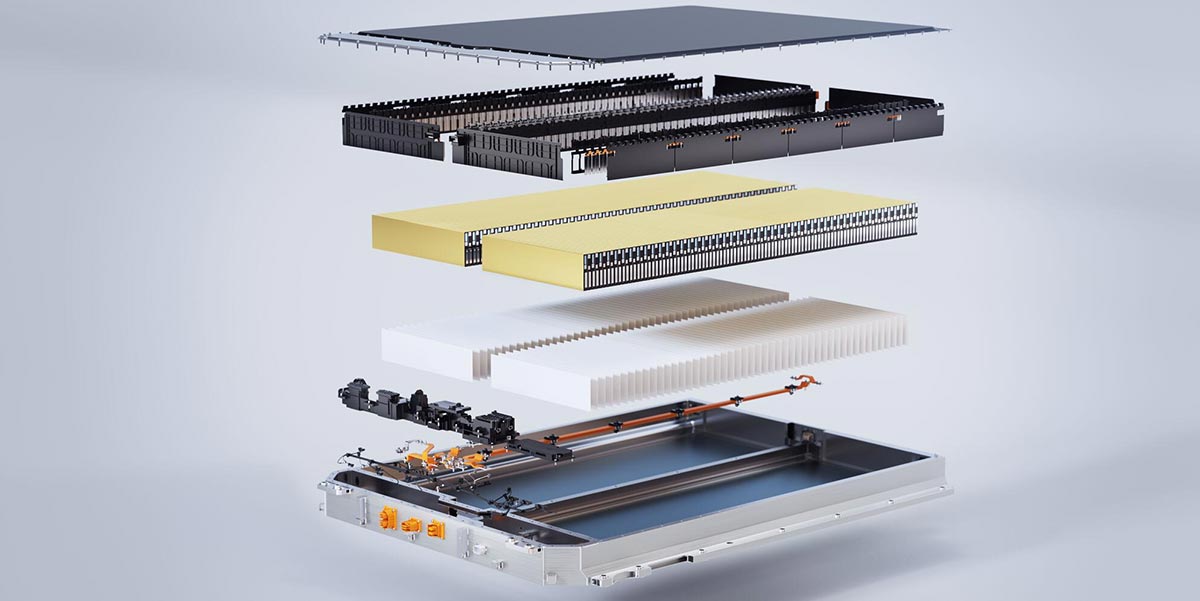

Chinese battery manufacturer Farasis Energy introduced its Super Pouch Solution (SPS) for electric cars at the China International Supply Chain Expo (CISCE). The SPS system utilizes semi-solid pouch cells directly integrated into the vehicle chassis, providing an energy density exceeding 220 Wh/kg.

While the specific test cycle for the claimed ranges of over 1,000 kilometers is not specified, the system is designed for capacities ranging from 80 to 150 kWh, dependent on the thickness of the horizontal pouch cells, ranging from 85 to 145 millimeters.

See also: Farasis Energy and Togg Embark on Joint Venture to Construct Battery Cell Factory

Farasis emphasizes the non-modular nature of the system, expecting it to increase energy density by more than 30% compared to conventional modular systems with similar volume. The SPS is positioned as compatible with various electric vehicle models, though the manufacturer does not elaborate further on this point.

The use of large semi-solid pouch cells, combined with an efficient liquid cold plate, reportedly enables a volume utilization of 75%, a reduction in component count by half, and a weight reduction of 20 to 30 kilograms compared to conventional battery systems. Additionally, material costs are said to be reduced by a third.

Farasis employs lightweight aluminium-plastic foils for encapsulation and an advanced stacking process in the new cells, surpassing the energy density of conventional prismatic and cylindrical cells of the same size by ten percent. The company claims charging and discharging rates of “2C to 6C and more,” facilitating fast charging for electric cars to achieve up to 400km of range in 10 minutes, with maintained high efficiency during energy release. However, the timeline for the availability of SPS cells has not been disclosed.

See also: Farasis Energy Develops Breakthrough Solution to Prevent Thermal Runaway in Latest Battery Cells

At CISCE, Farasis also showcased its electric vertical takeoff and landing (eVTOL) battery technology, battery system for electric motorcycles, and portable energy stations. Notably, details about the electric motorcycle or eVTOL battery system were not provided in the press announcement for the automotive industry.

Earlier this year, Farasis optimized its battery module design to prevent thermal runaway, with industrial production of the improved modules slated to commence in 2025. Stefan Bergold, General Manager of Europe at Farasis, previously highlighted the solution’s effectiveness in limiting thermal runaway to a single cell, preventing its spread to neighboring cells and the entire battery pack.