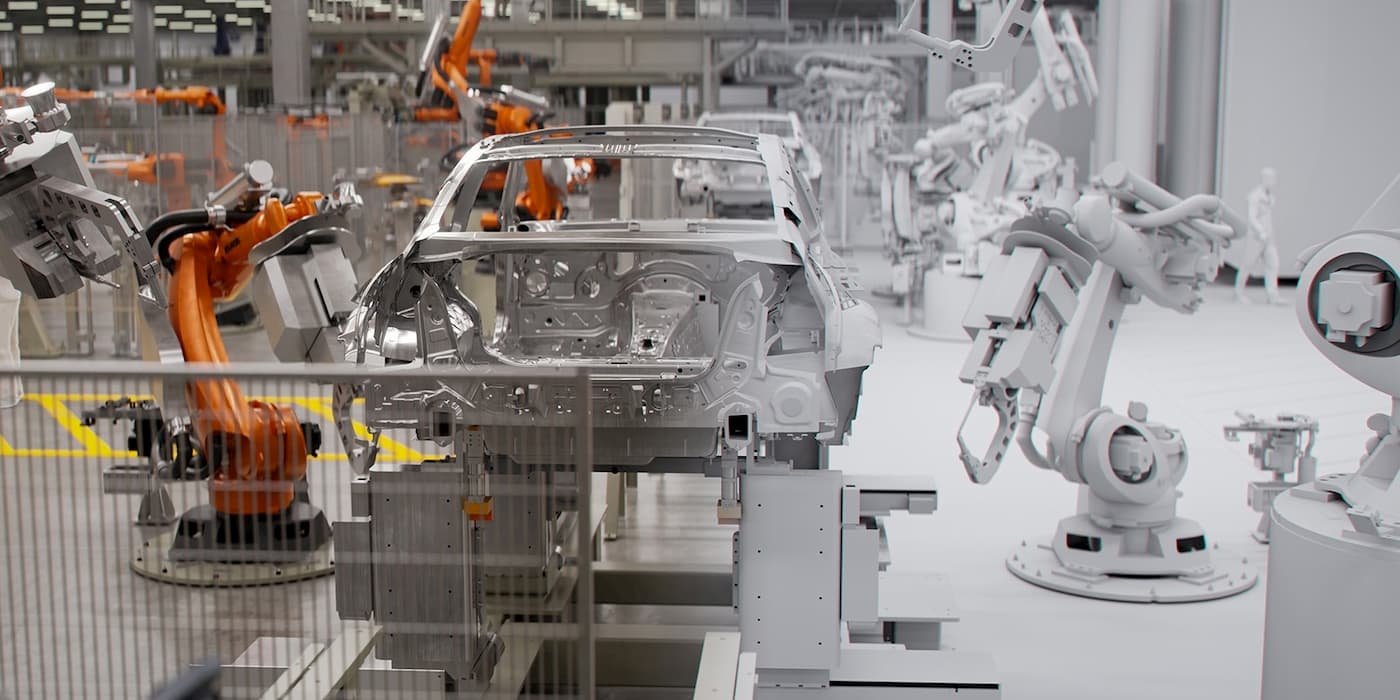

BMW is stepping into the future of vehicle production, as it is already manufacturing its next-generation all-electric Neue Klasse (new class) vehicles using advanced virtual computing technology. This week, BMW announced that it has opened the world’s first entirely virtual factory in the NVIDIA Omniverse platform to produce its Neue Klasse EVs. The platform is essentially the closest thing to the real world, using artificial intelligence to allow you to create and operate applications in the metaverse (virtually).

The technology, created by NVIDIA, allows BMW to create physically accurate, large-scale demonstrations bringing concepts to life in a new way, or a digital twin as it’s often called. Milan Nedeljković, head of production at BMW, explains that “With Nvidia and AI we set up new factories faster and produce more efficiently than ever. This results in significant savings for us.”

The NVIDIA Omniverse platform has become a game-changer in the manufacturing industry as it allows businesses to virtually plan and build factories in real-time. The platform uses AI and virtualization to accelerate and refine how BMW plans, resulting in faster decision-making and efficiency.

See also: BMW’s first Neue Klasse EV platform will debut in compact sedan and sporty SUV

Although construction of BMW’s EV plant in Hungary has just begun, the automaker is already manufacturing cars at the plant in the metaverse. The ability to see virtually in real-time how the facility will operate will ensure a smooth and efficient opening process.

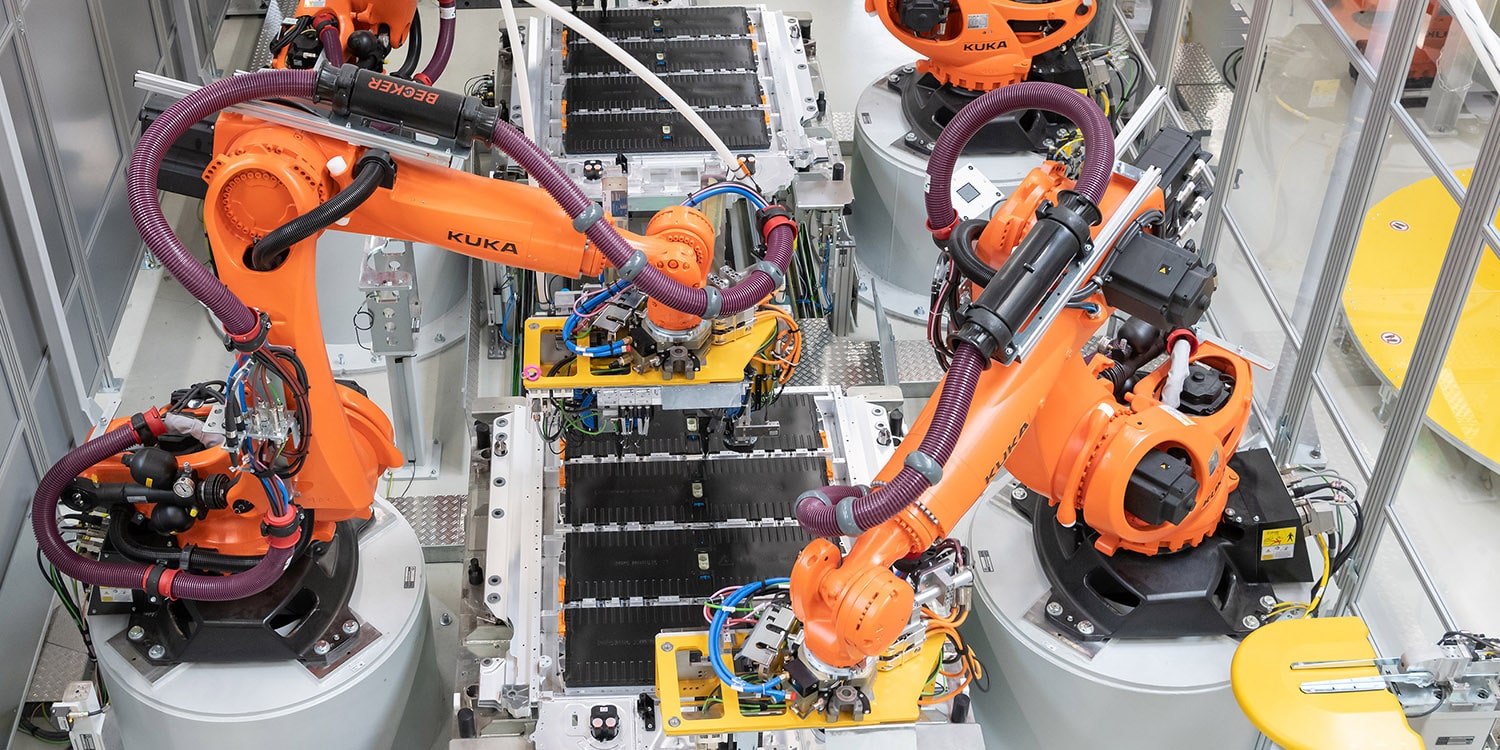

BMW and NVIDIA held a factory demo to showcase the power and efficiency of planning AI-based EV facilities using the Omniverse platform. In the joint demo, BMW’s global planning team joined Nedeljković and NVIDIA CEO and founder Jensen Huang on a virtual planning session for the factory’s new body shop. After learning a new production concept that needed changes (a robot placement), the team collaborated on a solution, visualizing the process in real-time as they went.

BMW’s virtual planning adds to its “masterplan for the automotive production of tomorrow,” dubbed the BMW iFACTORY. BMW introduced the production concept last year to focus on digitalization alongside green and resource-saving methods. The BMW Hungary plant is expected to open in 2025, where it will produce the company’s first next-gen Neue Klasse EVs as the automaker kicks off a new era.

See also: BMW’s Neue Klasse Platform can support for Supercar with quad-motor and 1,341 HP

In a statement, BMW said: “The new BMW Group factory in Debrecen will be a greenfield project with a comprehensive, state-of-the-art digital infrastructure from the ground up. It will showcase all the innovative technologies and digital processes of Industry 4.0. The BMW i4 and BMW iX models produced here will be fitted with the latest electric drivetrain technology and meet the highest standards of sustainability and resource efficiency.”