Chemical giant BASF and recycling specialist WHW Recycling have joined forces in a new partnership focused on processing cathode and anode waste to create new raw materials, aiming to enhance the sustainability of battery cell production in Europe.

The agreement enables WHW Recycling to complement BASF’s processes by processing cathode and anode foil waste from battery cell production. This collaboration will expand BASF’s recycling service offering for its customers, contributing to a more sustainable battery supply chain.

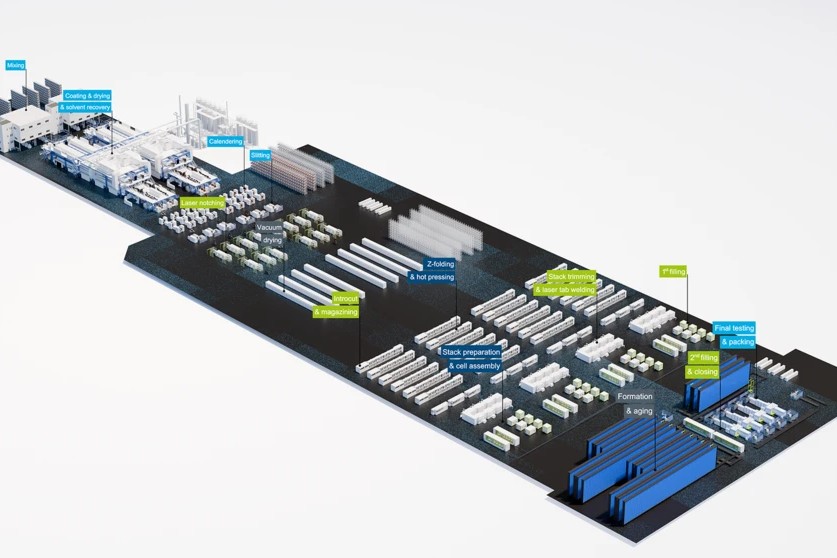

Starting from the end of this year, WHW Recycling’s two new separation plants in Baudenbach, Germany, will process and separate cathode and anode foil waste from battery cell production. BASF will then refine the resulting impure cathode active material to produce battery-grade minerals, which can be reused as raw materials for cathode active material production.

WHW Recycling, a joint venture between Walch Holding and Štefan Hanigovský, specializes in the recycling of electrode foil. The company utilizes a patented process to recover recyclable materials to a highly pure form, enabling the reuse of materials such as aluminium foil and copper used in the anode foil as a carrier material.

Štefan Hanigovský, joint venture partner of WHW Recycling, stated, “In collaboration with BASF, we continue our proven recycling processes. Our goal is to jointly be an important part of the battery recycling infrastructure and become a leader in the development of battery recycling technologies.”

This partnership comes as part of BASF’s broader efforts in battery recycling. In April, BASF launched its prototype metal refinery for battery recycling in Schwarzheide, Germany. The company aims to develop and optimize processes to recycle raw materials from old batteries and production waste, further advancing the circular economy in battery manufacturing.

The collaboration between BASF and WHW Recycling marks a significant step towards sustainable battery production, highlighting the importance of recycling in reducing the environmental impact of electric vehicles.