AVL List, a engineering firm specializing in energy and mobility solutions, has developed a groundbreaking approach to measuring and reducing the carbon footprint of batteries. The company is now advocating for the inclusion of a battery’s CO2 footprint in its passport, and it claims that its innovative approach can reduce CO2 in production by up to 30%.

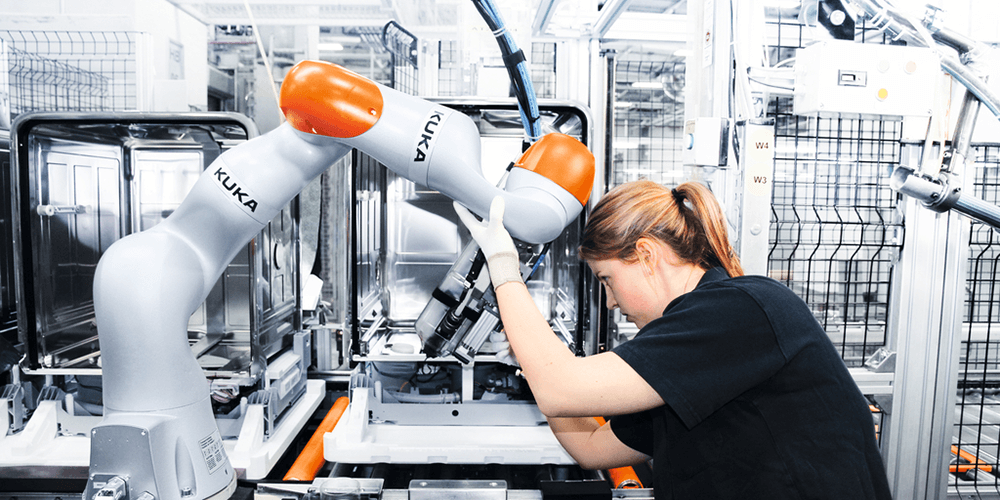

Unlike traditional methods that rely on estimates and random checks, AVL’s approach involves using sensors that measure the amount of energy used in each manufacturing step. By doing so, the company can accurately determine energy consumption during production and provide manufacturers with data that can help them optimize their entire process chain.

AVL opened its Battery Innovation Center in Graz in September 2021, where it compiles the data and makes it available to others. According to the company, its approach provides exact, real-time measurements of a battery’s carbon footprint, which is a significant improvement over traditional methods that rely on outdated values from databases.

“CO2 emissions in battery component production must be reduced as quickly as possible. Real measurements in the production process support this. Only what can be measured can be improved,” says Uwe Grebe, Executive Vice President at AVL.

AVL’s data is compiled in a digital twin of the battery, which can be processed and encrypted for inclusion in the EU battery passport. The passport is used to establish a digital twin that conveys information about all applicable sustainability and lifecycle requirements. AVL is working closely with Austrian startup Tributech to notarize and distribute the data so that every participant in the system has the data relevant to them at the right time.

AVL’s innovative approach to measuring and reducing the carbon footprint of batteries has the potential to revolutionize the industry. By providing real-time data, manufacturers can adjust their production processes and reduce their carbon footprint significantly. The inclusion of a battery’s CO2 footprint in its passport is a crucial step towards achieving greater sustainability in the industry.

, a leading engineering firm specializing in energy and mobility solutions, has developed a groundbreaking approach to measuring and reducing the carbon footprint of batteries. The company is now advocating for the inclusion of a battery’s CO2 footprint in its passport, and it claims that its innovative approach can reduce CO2 in production by up to 30%.

Unlike traditional methods that rely on estimates and random checks, AVL’s approach involves using sensors that measure the amount of energy used in each manufacturing step. By doing so, the company can accurately determine energy consumption during production and provide manufacturers with data that can help them optimize their entire process chain.

AVL opened its Battery Innovation Center in Graz in September 2021, where it compiles the data and makes it available to others. According to the company, its approach provides exact, real-time measurements of a battery’s carbon footprint, which is a significant improvement over traditional methods that rely on outdated values from databases.

“CO2 emissions in battery component production must be reduced as quickly as possible. Real measurements in the production process support this. Only what can be measured can be improved,” says Uwe Grebe, Executive Vice President at AVL.

AVL’s data is compiled in a digital twin of the battery, which can be processed and encrypted for inclusion in the EU battery passport. The passport is used to establish a digital twin that conveys information about all applicable sustainability and lifecycle requirements. AVL is working closely with Austrian startup Tributech to notarize and distribute the data so that every participant in the system has the data relevant to them at the right time.

AVL’s innovative approach to measuring and reducing the carbon footprint of batteries has the potential to revolutionize the industry. By providing real-time data, manufacturers can adjust their production processes and reduce their carbon footprint significantly. The inclusion of a battery’s CO2 footprint in its passport is a crucial step towards achieving greater sustainability in the industry.