Tesla has engaged more than 400 tier-1 local suppliers in China, with over 60 integrated into its global supply chain system, according to Chinese media reports.

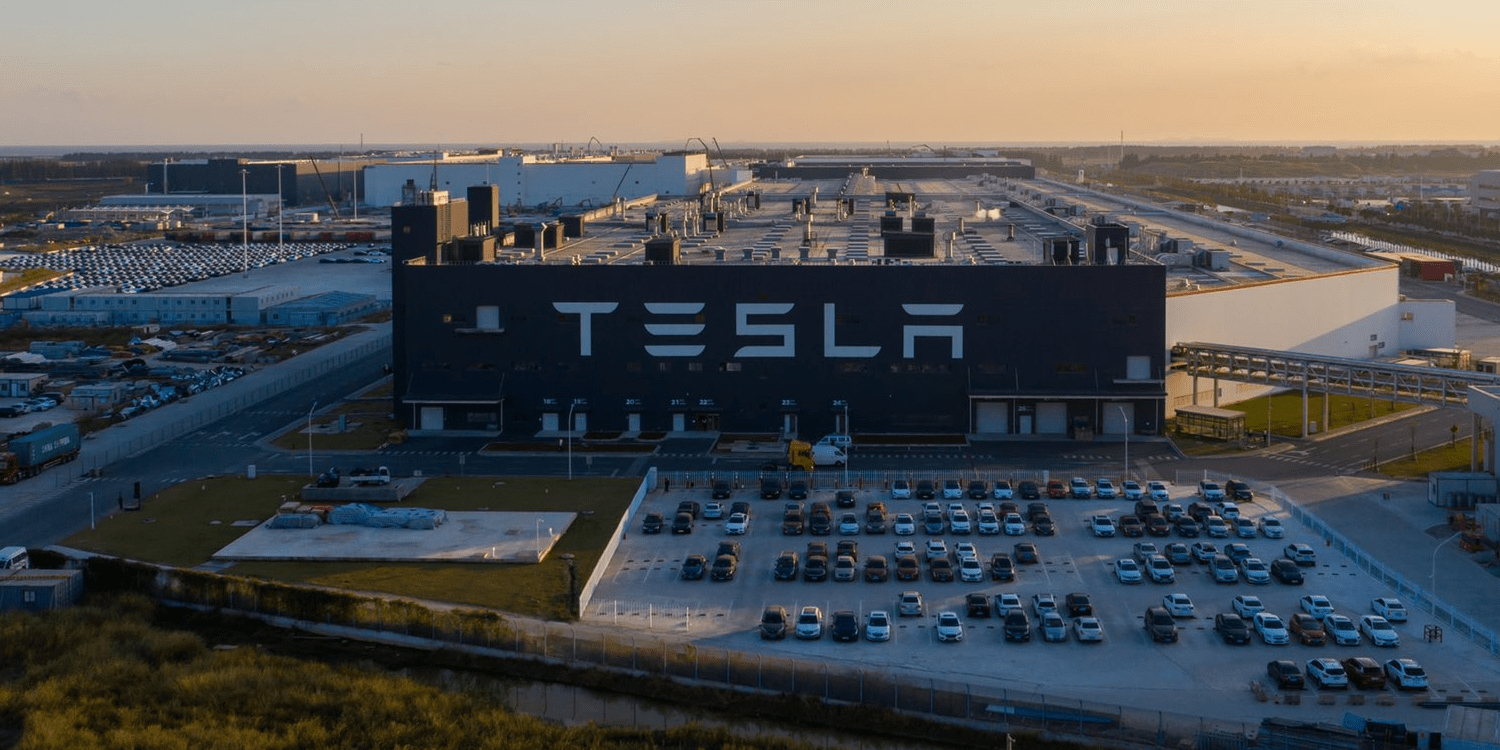

The company’s Shanghai factory, operational since late 2019, sources over 95% of its components locally, reflecting its reliance on regional suppliers for production efficiency. As Tesla’s first wholly foreign-owned auto manufacturing project in China, the Shanghai facility began producing Model 3 sedans in early 2020 and Model Y crossovers a year later.

In the first three quarters of 2024, the Shanghai plant delivered 675,758 vehicles, accounting for over half of Tesla’s global deliveries during that period. The factory’s efficiency has been highlighted, with vehicles rolling off the assembly line at an average interval of approximately 30 seconds.

Tesla showcased its China-made Model Y and Model 3 vehicles, along with other locally produced components, at the China International Supply Chain Expo (CISCE) in Beijing. The event reflects Tesla’s efforts to integrate local suppliers further into its production ecosystem while strengthening its position in the international supply chain.

In October, Tesla China recorded sales of 68,280 vehicles, including 27,795 exported units. While local sales rose 41% year-on-year, they marked a decline from September’s numbers. From January to October, Tesla’s China sales reached 500,685 vehicles, surpassing the 500,000-unit milestone and growing by 8.3% year-on-year.

The Shanghai facility’s contribution remains vital to Tesla’s global operations, ensuring a steady supply of vehicles for both domestic and international markets.