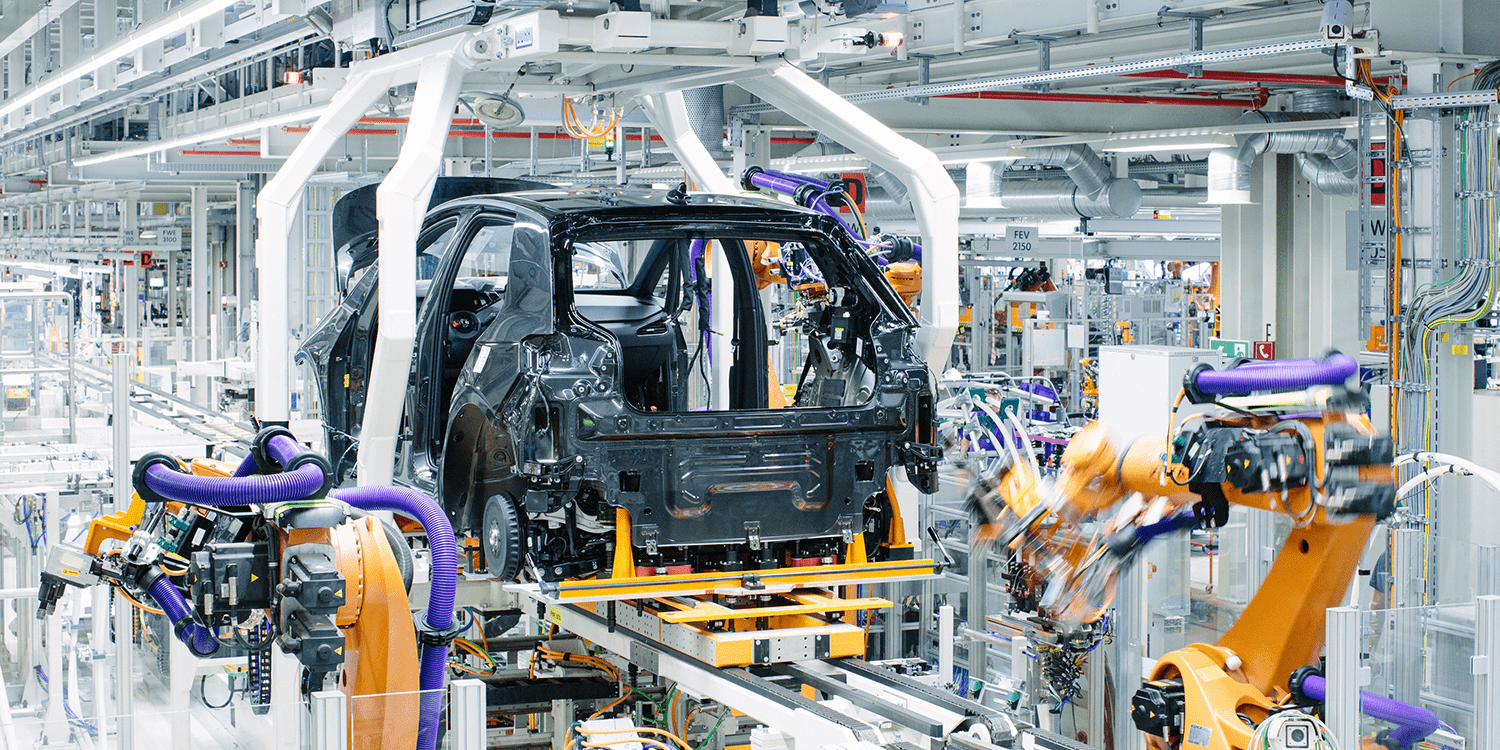

Volkswagen (VW) is set to suspend production on its production line 2 at the Zwickau plant starting December 1 due to a shortage of electric motors, as reported by the Freie Presse. Models affected by the production halt include VW’s ID.4 and ID.5, along with Audi’s Q4 e-tron and Q4 Sportback e-tron. More than 1,000 of the approximately 8,000 employees at the facility will be significantly impacted, according to the statement. Despite the setback, VW has committed to continuing employee payments during the hiatus, offering training, and seeking improvements in work processes.

The production disruption is attributed to supply chain challenges for the new APP550 electric motor at the VW component plant in Kassel. This motor, introduced in the recent model year for the mentioned SUVs, boasts 210 kW of power and 550 Nm of maximum torque, representing an upgrade from its predecessor. However, the supply chain disruptions have led to fewer deliveries of the high-performance electric motor than initially planned for the Zwickau plant. VW has confirmed this development, underscoring the impact on production.

To mitigate the effects on the ramp-up of the new VW ID.7 production in Emden, the few available APP550s will be redirected to another plant, taking precedence over Zwickau’s production line 2. Meanwhile, production on Zwickau’s production line 1, responsible for manufacturing the VW ID.3 and Cupra Born models, remains unaffected. These models continue to utilize the older electric drive with 150 kW of power and 310 Nm of torque, and there are no reported disruptions in their supply chain.

Notably, Volkswagen had previously halted electric vehicle production in Zwickau on production line 1 for approximately two weeks in October due to weak demand. However, production resumed in three shifts following this brief pause.

Looking ahead, Zwickau remains a crucial site for VW’s electric mobility future. The plant is slated to produce the first model based on the upcoming SSP electric platform, the VW Trinity. Additionally, the VW engine plant in Chemnitz will contribute components for the SSP platform, emphasizing the strategic shift towards electric mobility at the site. Plant manager Gerd Hahn anticipates that the thermal management system for the SSP platform, scheduled for series production in 2028, will mark a more compact, lighter, and cost-effective solution compared to previous systems. Initial deliveries of these systems are expected to commence in 2026, reinforcing the site’s commitment to electric mobility.