Automotive Cells Company (ACC), a joint venture by Stellantis, Total, and Mercedes-Benz, recently opened its first factory in France. While the inauguration marks a significant milestone, the commissioning process will occur later this year.

The new facility, located in Billy-Berclau/Douvrin in the Hauts-de-France region, boasts a production area exceeding 60,000 square meters. The initial production line, scheduled to commence battery cell production before the end of 2023, has an annual capacity of over 13 GWh. ACC aims to achieve this output by the end of 2024. Furthermore, two additional production lines are planned, which will increase the plant’s capacity to 40 GWh per year by 2030.

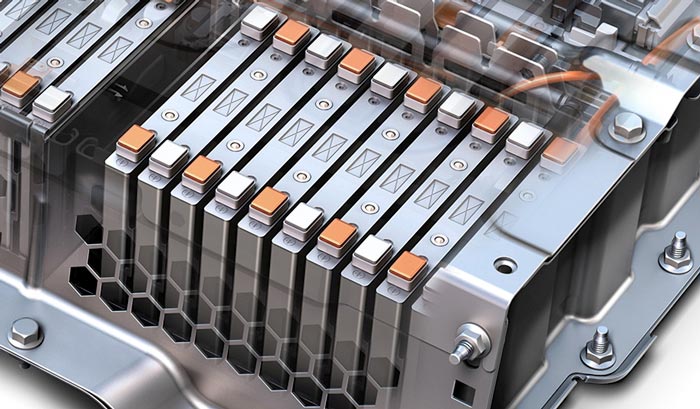

Among the production space, 20,000 square meters are designated as a Dry room. Sixteen mixers, each with a volume of 1,600 liters, have been installed in the hall for mixing active materials and auxiliary substances. Coating lines, with three dedicated to cathodes and two to anodes, coat carrier foils, which are then dried at a speed of 80 meters per minute in ten to twelve ovens. After cutting and stacking, the plant aims to produce 56,000 cells per day, equivalent to approximately 2.4 million battery modules or 200,000 to 300,000 electric vehicles per year, depending on the number of modules per vehicle. This capacity corresponds to the initial 13 GWh production of the plant, referred to as “Block 1.”

ACC has plans to establish three factories, each with a capacity of 40 GWh. For the Douvrin production, the company has utilized processes tested and optimized at the pilot plant in Nersac, located in western France since 2020. The research and development center in Bruges near Bordeaux, which began operations in 2020, laid the groundwork for ACC’s first battery factory. The investment of €850 million in the site facilitated an increase in the planned production capacity. Initially, Douvrin and the parallel plant in Kaiserslautern were announced with a capacity of 24 GWh, but this figure was later raised to 40 GWh.

The planning for the battery factory was initially initiated by PSA and the Total subsidiary Saft. Following the merger of PSA and FCA to form Stellantis Group, the acquisition of the Termoli site in Italy became the third ACC location. ACC aims to achieve a total capacity of 120 GWh with the commissioning of the factories in Kaiserslautern from 2025 and Termoli from 2026, both designed for up to 40 GWh.

ACC considers the battery factory in Douvrin to be a European flagship, not only due to its facilities in Germany and Italy but also because of the support received from France, Germany, Italy, and the European Union. Mercedes-Benz later joined the cooperation between Stellantis and Total.

The companies and politicians involved have expressed concerns not only about the European supply of battery cells but also about sustainability and the environmental impact of production. ACC states that the Douvrin factory will use significantly less water than a standard vehicle manufacturing factory and plans to recycle 90% of waste. ACC has committed to sourcing strategic materials for its batteries, such as cobalt, lithium, copper, and nickel, from suppliers with a strong focus on environmental and human rights standards. The company also aims to contribute actively to the development of the battery recycling industry.

According to ACC’s press kit, the factory is expected to consume 230,000 cubic meters of water per year, with 90% used for industrial processes and the remaining 10% for drinking water. Additionally, ACC estimates that for the

initial 13 GWh production block, the factory will require 362 GWh of energy per year, equivalent to the capacity of about 20 modern wind turbines. Based on these calculations, the energy consumption per vehicle battery amounts to 1,200 kWh, considering that the batteries produced this way can power up to 300,000 cars.

ACC CEO Yann Vincent expressed pride in developing battery technology in France and emphasized the commitment to European industrial sovereignty in the strategic battery sector, which is currently dominated by competition from Asia. He stated, “With this inauguration, all ACC employees are dedicated to contributing to the ecological transition of transport through the production of innovative batteries.”

The three shareholders also have high expectations for ACC. Mercedes CEO Ola Källenius sees the plant as a crucial step in making the auto industry more resilient, competitive, and sustainable in the electric era. Stellantis CEO Carlos Tavares anticipates ACC producing high-tech batteries that promote clean, safe, and affordable mobility for all. Tavares also noted the symbolic significance of battery production starting at the same location where Stellantis previously produced internal combustion engines. TotalEnergies CEO Patrick Pouyanné stated that the company’s investments aim to strengthen electrification and contribute to the transformation of the European energy landscape and the emergence of a more sustainable economy.