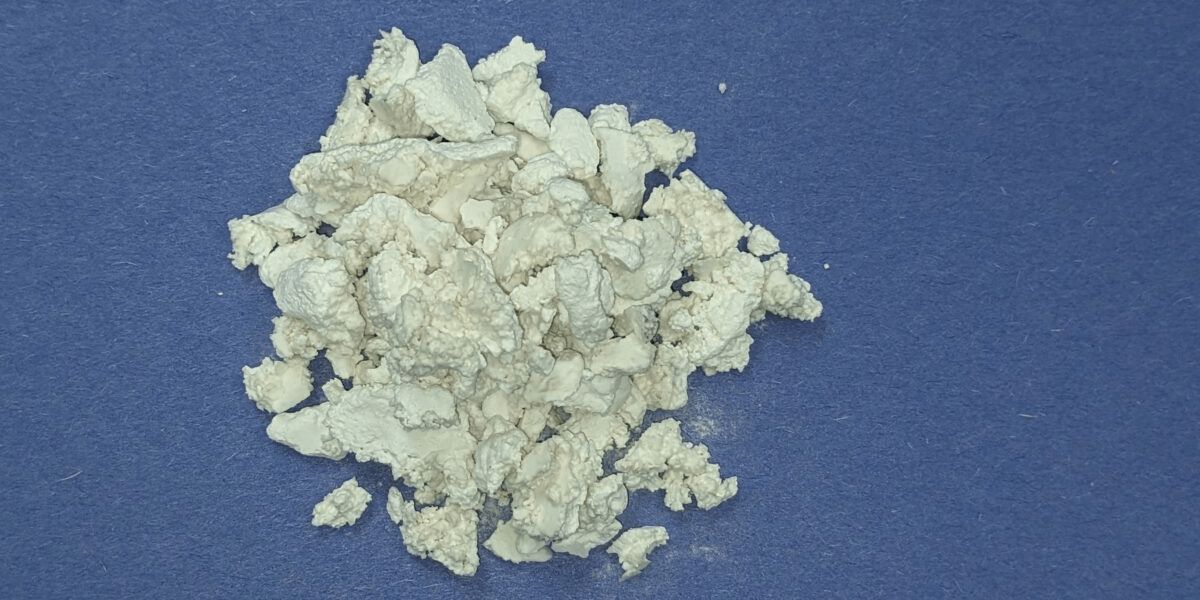

Electra Battery Materials Corporation, a Canadian company formerly known as First Cobalt, has achieved a major breakthrough in its efforts to recover lithium from expired batteries through its proprietary hydrometallurgical process. The company recently completed a black mass recycling trial at its refinery north of Toronto and has successfully recovered lithium, nickel, cobalt, manganese, copper, and graphite.

The successful recovery of lithium in a plant-scale setting validates Electra’s efforts in commissioning its larger refinery complex, and the company has decided to extend its black mass processing and recovery activities through June 2023, beyond its initial target of 75 tonnes. The decision was made due to the positive test result and the interest expressed by potential partners in the project.

Electra’s ability to recycle lithium from expired batteries through hydrometallurgy represents a potential game changer for the North American EV supply chain. It lowers the carbon footprint of manufacturing electric vehicles and provides an important source of future supply for a commodity whose demand is expected to grow significantly in the coming years.

The successful black mass recycling trial has considerably strengthened the economics of Electra’s battery recycling strategy by providing another high-value product the company can sell. Electra already has a supply agreement with LG Energy Systems for the delivery of cobalt sulphate to manufacture batteries, and with LG Energy Systems still in the process of negotiating supply deals for lithium in North America, the company is a prime candidate as a potential partner.

Electra’s success in recovering lithium from expired batteries through hydrometallurgy highlights the importance of sustainable and environmentally-friendly practices in the manufacturing of electric vehicles. The company’s efforts serve as an inspiration to others in the industry to explore new and innovative ways to reduce the carbon footprint of electric vehicle production and increase the sustainability of the entire supply chain.