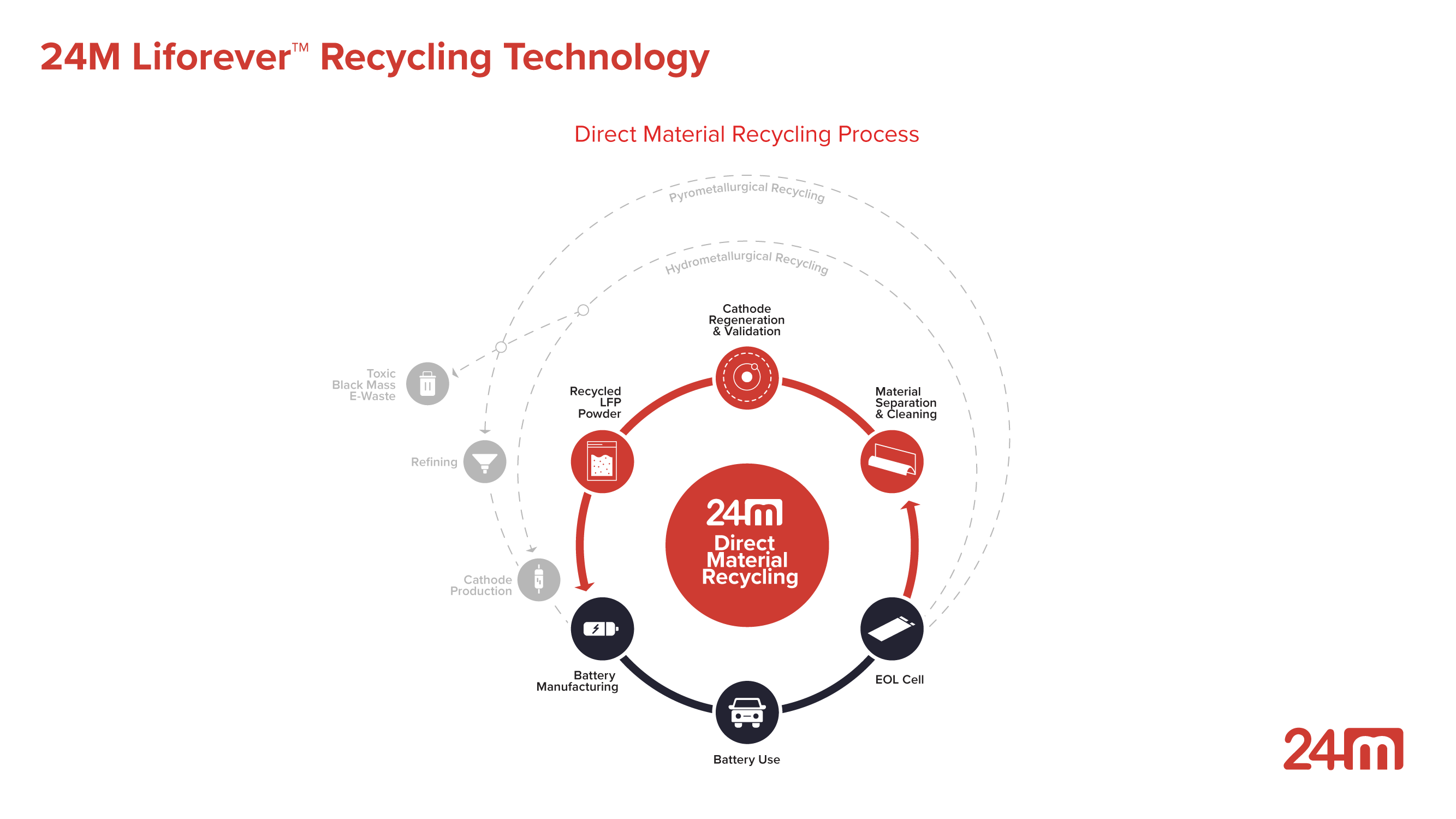

MIT spinout and battery manufacturer 24M Technologies has introduced a revolutionary direct-material battery recycling process, Liforever, designed for electric vehicle (EV) batteries and energy storage systems. The new process, integrated into 24M’s battery manufacturing process, aims to significantly improve the efficiency and cost-effectiveness of battery recycling.

24M Technologies, based in Cambridge, Massachusetts, has developed a unique battery design called “SemiSolid,” featuring gooey electrodes that simplify lithium-ion battery production. This design reduces production costs by up to 40% while enhancing the batteries’ energy density, safety, and recyclability.

See also: Volkswagen Explores Dry Coating Process to Enhance Electric Car Battery Production

According to 24M Technologies CEO Naoki Ota, “Better battery recycling is essential for a sustainable energy future, but the use of binders in conventional cell production has made direct recycling impractical. Liforever solves these challenges by enabling the reuse of nearly every part of the battery cell without requiring the expensive, inefficient, and environmentally challenging processes used in conventional cell recycling.”

Traditional lithium-ion battery recycling methods are costly and toxic, resulting in a type of e-waste known as black mass. This process damages key battery materials, making recycling less economically viable, particularly for cheaper materials like lithium iron phosphate (LFP). Typically, only the more expensive metals are salvaged for reuse.

Liforever, however, preserves the battery’s active materials in their original form, eliminating the creation of black mass entirely. This breakthrough allows for the recycling of all active materials, including those from the anode and cathode. Once recovered, the materials are cleaned and, if necessary, re-lithiated to restore them to their original performance levels.

Moreover, 24M Technologies asserts that the Liforever recycling methodology complies with current and anticipated future recycling regulations. The company’s SemiSolid process is chemistry agnostic, meaning Liforever can support next-generation batteries of all chemistry types.