Volvo Construction Equipment (Volvo CE) has shown that the Swedish construction equipment manufacturer is relentless in developing new innovations that are in line with its commitment to driving change towards a green future.

This time, the Volvo Group subsidiary has introduced the Volvo HX04 which is the prototype of the world’s first hydrogen-cell articulated haul truck (mining truck), which is now on trial.

This sustainability innovation follows a multi-stakeholder research project that aims to break new ground in hydrogen technology. This project will also be an important Volvo CE innovation in providing hydrogen-powered construction equipment in the future.

As part of its mission to be a sustainable resource, Volvo CE also acknowledges that it has stepped up on the commitment of the Science Based Targets Initiative (SBTi) for a clean greenhouse gas emission chain by 2040 and is driving the industry’s transformation towards carbon neutrality.

Carolina Diez Ferrer, Head of Advanced Engineering Programs at Volvo CE, said that this innovation will provide valuable insight into hydrogen’s opportunities in energy transformation with battery-electric solutions.

“Being the inventor of the world’s first articulated carrier more than 55 years ago, we are pleased and proud to again drive change with this fuel cell carrier concept,” he explained in his official statement, Wednesday (15/6/2022).

“We believe that by exploring different technologies and working in partnership, we can create the best path forward for decarbonizing the construction industry.”

The Volvo HX04 is the result of a research project running between 2018 and 2022, with funding from FFI, the Swedish Innovation Agency Vinnanova, the Swedish Energy Agency and the Swedish Transport Administration, to support research, innovation and strategic development of sustainable vehicles.

In addition, Volvo CE is also establishing partnerships with several other companies, one of which is Shell which will provide infrastructure for a fast hydrogen cell fueling station on the Volvo CE test track at the Braas, Sweden facility where the Volvo HX04 truck is made.

“Providing the refueling infrastructure for this innovative project gives Shell the opportunity to demonstrate our technical capabilities in hydrogen, and allows us to support one of our key global collaboration partners in taking another step forward,” said Oliver Bishop, General Manager Hydrogen Mobility at Shell.

With the state-of-the-art filling station, the Volvo HX04 truck will be able to refill a hydrogen cylinder in about 7.5 minutes and allow the prototype vehicle to operate for approximately 4 hours.

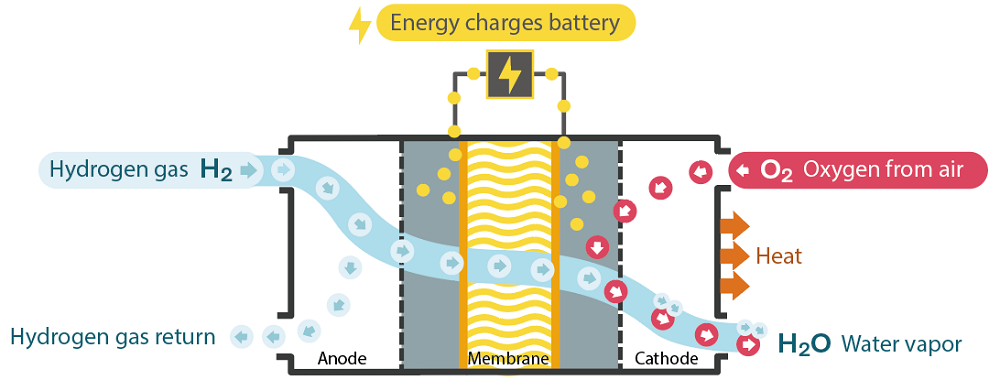

The fuel cell on the truck will work by combining hydrogen with oxygen and a chemical reaction that produces electricity to propel the engine. In the process, the hydrogen fuel cell on the Volvo HX04 can also generate heat that can be used to warm the cabin space.