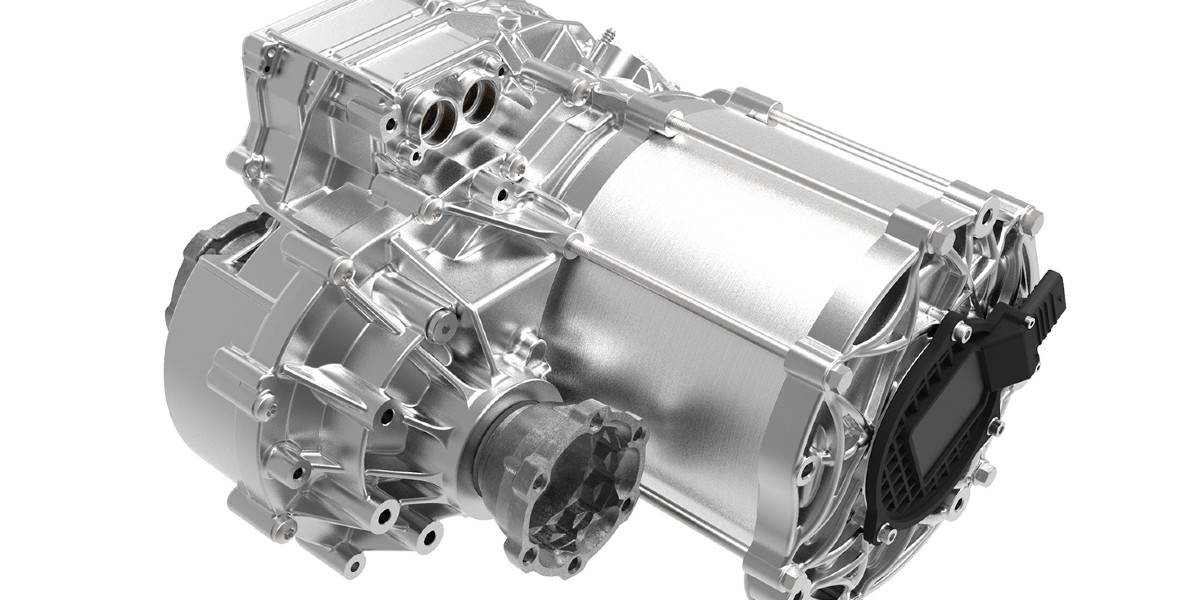

Vitesco Technologies, a leading supplier of electrification solutions for vehicles, has unveiled a new option for the fourth generation of its EMR4 electric axle drive platform. The platform now includes a new rotor that uses electromagnets rather than permanent magnets. This innovative rotor design makes the EMR4 an externally excited synchronous machine (EESM) that eliminates the need for rare earth materials and reduces costs.

The EMR4, which was introduced in July 2021, can be designed as a permanently excited synchronous machine (PSM) and cover the power spectrum from 80 to 230 kW, depending on customer requirements. The latest variant showcased at the Vienna Motor Symposium 2023 replaces the PSM rotor with permanent magnets with the new rotor using electromagnets. According to Vitesco, the EESM rotor with its “sophisticated winding technology” is an economical option that can deliver advantages, particularly with more powerful electric motors.

See also: Vitesco recieves major order worth around two billion euros for electric vehicles drive system

Vitesco has overcome design hurdles to achieve the same power class for both PSM and EESM with targeted design changes. This means that both options can use the same installation space. The EESM rotor saves costs associated with permanent magnets and also eliminates the carbon dioxide emissions associated with their extraction and processing.

The EESM option requires an additional module in the inverter to control the coils, but Vitesco is close to delivering an EESM plug-and-play solution. The new rotor design also brings other advantages such as a reduction in power requirements and higher sustainability.

“The externally excited rotor without permanent magnets is a particularly sustainable option for our customers,” said Thomas Stierle, Head of the Electrification Solutions Division at Vitesco Technologies. “The higher the performance requirements of the drive, the more economically attractive EESM technology becomes. Top results in the sustainability and efficiency of electric cars will be achieved if the vehicle drive is optimally adjusted to the specific scenario.

Vitesco’s innovation is another step towards developing sustainable, efficient electric cars that deliver top performance. The EESM option is a game-changer for the industry, providing customers with a cost-effective, environmentally friendly solution that meets their specific requirements.