Global lithium production has more than tripled in the last decade, driven by the increasing demand for lithium-ion batteries. However, current methods of extracting lithium from rock ores or brines are slow, energy-intensive, and environmentally costly. Additionally, these methods rely on sources of lithium that are highly concentrated and limited to a few countries.

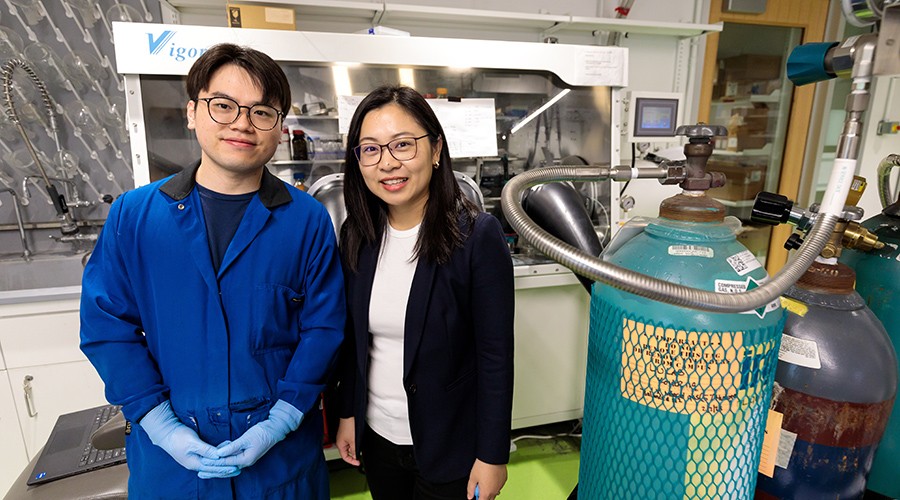

To address these challenges, researchers at the University of Chicago Pritzker School of Molecular Engineering (PME) have optimized a new method for extracting lithium from more dilute sources of the mineral, including seawater, groundwater, and “flowback water” from fracking and offshore oil drilling.

The research, published in Nature Communications, focuses on using particles of iron phosphate to efficiently extract lithium from dilute liquids. The particles, when designed correctly, can selectively pull lithium out of the liquid while excluding sodium ions, which are also present in briny liquids but are less desirable for extraction.

Lead researcher Chong Liu, Neubauer Family Assistant Professor of Molecular Engineering, explains that their method could significantly broaden the potential sources of lithium and help bridge the gap between demand and production.

The research team synthesized olivine iron phosphate particles of different sizes and shapes and tested their ability to selectively isolate lithium over sodium. They found that there was an optimal particle size range that maximized the efficiency of lithium extraction while minimizing the inclusion of sodium.

This optimized method could lead to faster, greener lithium extraction and help secure the lithium supply, particularly in countries with limited access to concentrated lithium sources. The research was supported by the National Science Foundation and the Department of Energy Office of Science.