Stellantis has made a significant announcement in the realm of electric vehicle (EV) technology, revealing plans to integrate solid-state batteries into the Dodge Charger Daytona by 2026. While this news is certainly exciting, it is essential to note that the initial rollout will consist of a demonstration fleet, aimed primarily at testing the technology in real-world conditions.

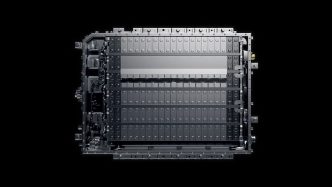

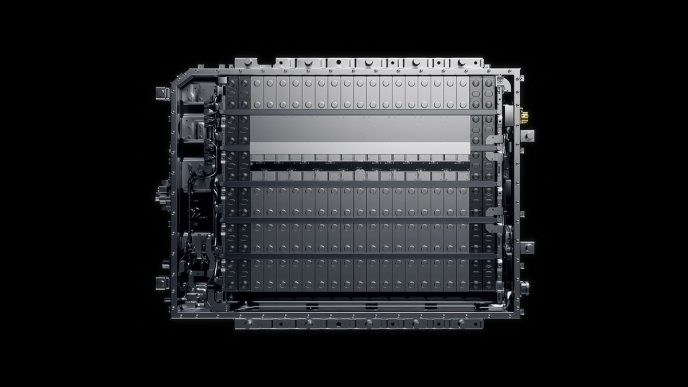

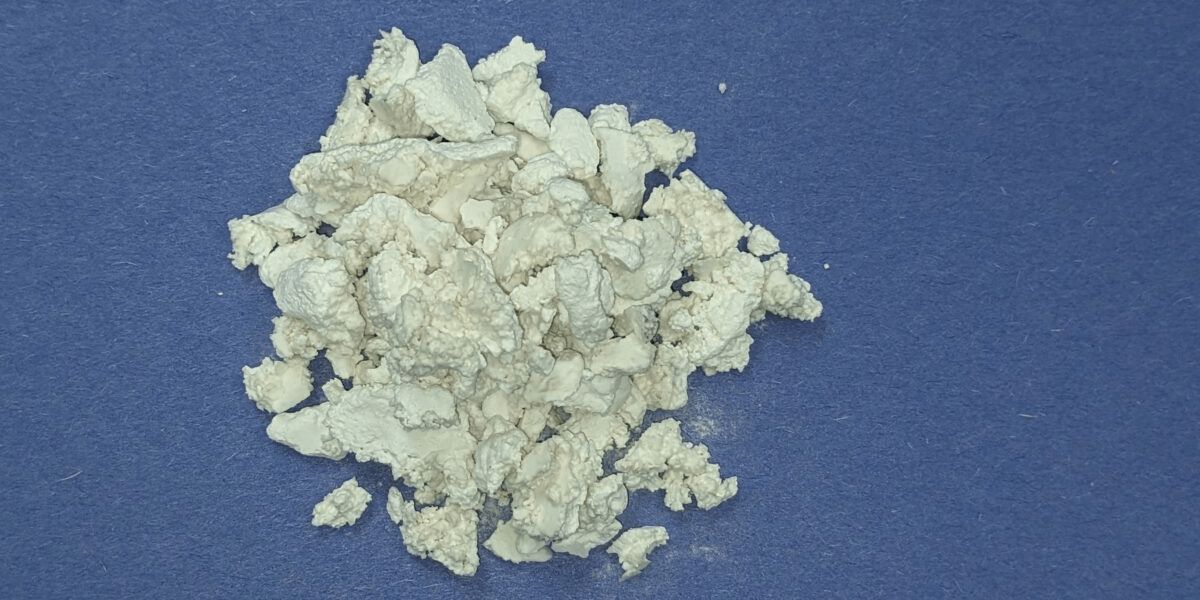

The prototypes of the Charger Daytona will feature solid-state batteries developed by Factorial Energy, boasting an impressive energy density exceeding 390 Wh/kg. Although specific details about the battery performance remain scarce, both Stellantis and Factorial emphasize the numerous advantages of this innovative technology over traditional lithium-ion batteries. These advantages include a higher energy density, reduced weight, enhanced performance, and the potential for a decrease in total vehicle costs over time. This combination of features positions solid-state batteries as a game-changer in the EV sector.

In pursuit of commercializing this technology, Stellantis and Factorial are taking crucial steps to validate the battery’s capabilities. The prototypes will undergo rigorous testing to assess their performance under various driving conditions. This initiative is part of Stellantis’s broader strategy to enhance its electric vehicle lineup and cater to the growing demand for high-performance, efficient EVs.

Ned Curic, Stellantis’ Chief Engineering and Technology Officer, emphasized the importance of this integration, stating, “By integrating Factorial’s innovative battery solution into the STLA Large platform, we are validating its potential to enhance our electric vehicle lineup, ensuring customers benefit from improved performance, longer driving ranges, and faster charging times in the coming years.” This investment underscores Stellantis’s commitment to leading the charge in EV innovation, having invested $75 million in Factorial back in 2021.

In addition to advancements in battery technology, Stellantis has recently unveiled a state-of-the-art wind tunnel featuring “moving ground plane” technology at its research and development center in Auburn Hills, Michigan. This upgraded facility is designed to enable Stellantis to measure and significantly reduce airflow resistance caused by wheels and tires, which can contribute to as much as 10% of total real-world aerodynamic drag.

The introduction of this high-tech wind tunnel is a critical development for future electric vehicles. By improving the aerodynamics of their models, Stellantis aims to increase the driving range of its EVs or potentially allow for the use of smaller, more cost-effective batteries. The new wind tunnel also incorporates advanced automation capabilities, streamlining the testing process. As noted by Stellantis, adjustments to wheelbase and track testing, which typically required up to two hours in conventional wind tunnels, can now be completed in just minutes.

This focus on aerodynamic efficiency is particularly relevant given Stellantis’s emphasis on larger vehicles built on the STLA Large and STLA Frame platforms, which are tailored for the North American market.