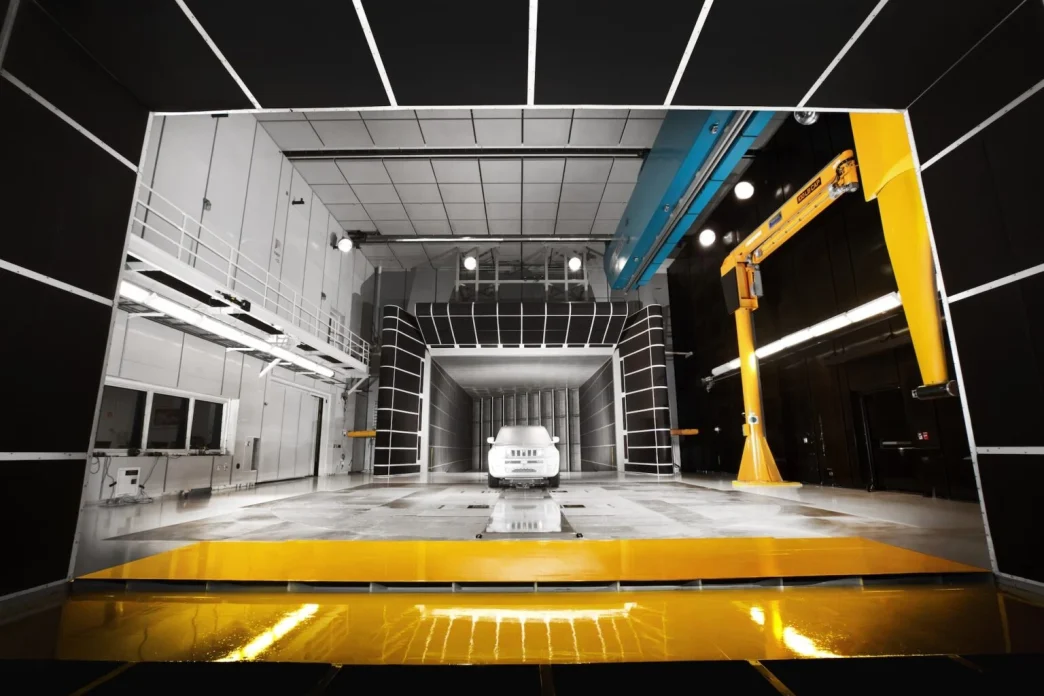

Stellantis has announced a significant investment of $29.5 million to upgrade its wind tunnel at the Auburn Hills research and technical center by incorporating Moving Ground Plane (MGP) technology. This enhancement aims to reduce drag and improve the aerodynamics of electric vehicles (EVs), ultimately enhancing their driving range and efficiency. The MGP technology allows for the simulation of real-world travel conditions, making aerodynamic testing more precise and expediting the development process of battery electric vehicles (BEVs).

The upgraded wind tunnel, equipped with MGP technology, will enhance the ability to measure and minimize airflow resistance, particularly from wheels and tires, which are significant contributors to aerodynamic drag. By addressing airflow resistance, Stellantis aims to extend EV driving range and may even lead to reductions in battery size, thereby improving both vehicle efficiency and design.

This investment aligns with Stellantis’ Dare Forward 2030 strategy, which includes a commitment to achieving carbon net-zero emissions by 2038 and aims for BEVs to account for 50% of U.S. sales and 100% of European sales by 2030. The new technology also incorporates automation capabilities, allowing for faster wheelbase and track testing, significantly reducing the time needed for these processes from hours to mere minutes.

“Range is a core consideration for customers who are transitioning to cleaner mobility through battery power,” remarked Mark Champine, senior vice president and head of North America engineering technical centers. He emphasized the importance of this investment, stating, “By reducing drag, we improve electric vehicle range and, ultimately, the overall customer driving experience.”

Additionally, the wind tunnel upgrade will bolster virtual development tools by providing more accurate simulations, accounting for factors such as tire deformation that can affect aerodynamics. Champine noted that the integration of real-time data collection and automation will accelerate the time to market for new vehicle designs.

This enhancement is part of a broader $85 million commitment by Stellantis to boost its research and development capabilities. The MGP system utilizes high-pressure compressed air to drive wheel and center belts, achieving speeds of up to 140 mph, while the facility is capable of generating wind speeds exceeding 160 mph, creating a robust testing environment for aerodynamic research.

Stellantis has a rich history of aerodynamic innovations, including the Chrysler AirFlow and contributions to NASA’s Mercury Redstone Rocket design. The company’s focus on aerodynamic excellence is evident in its models, such as the 2025 Ram 1500 and Chrysler Pacifica, which lead their segments in drag coefficients.