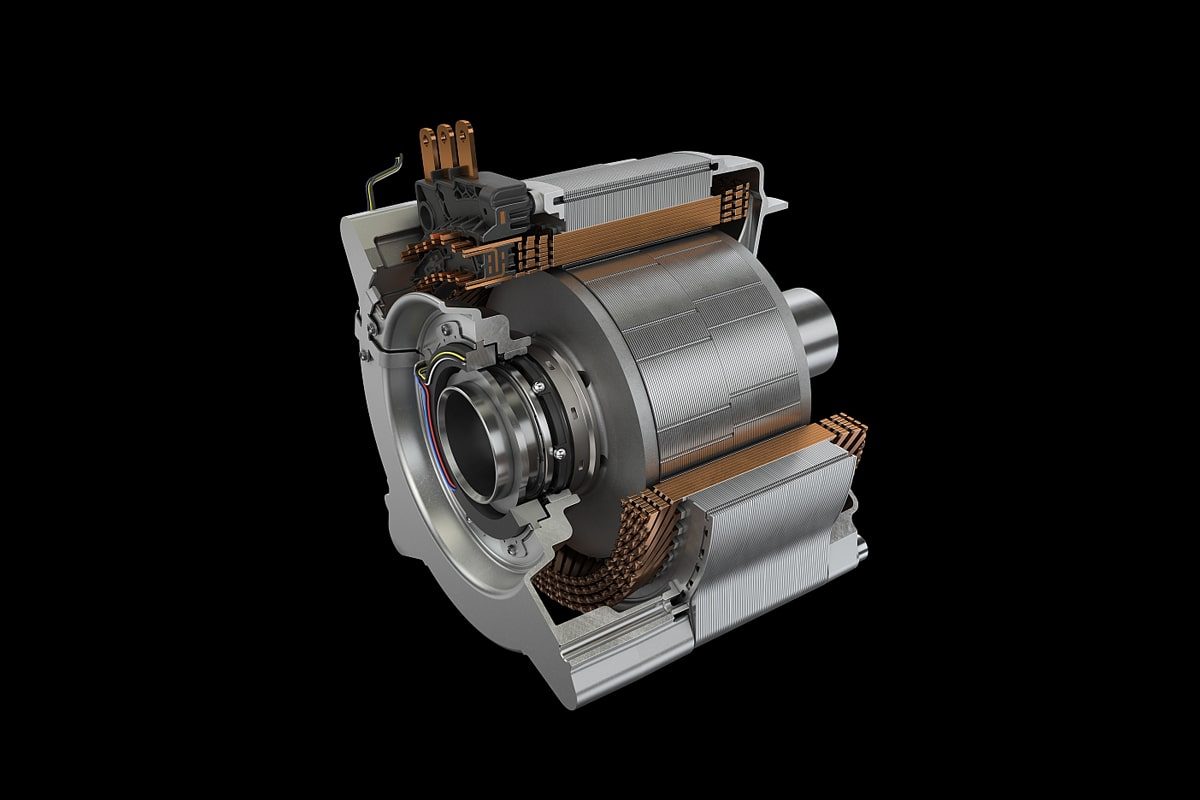

In the REASSERT research initiative, a collaborative team involving Schaeffler, the Fraunhofer Institute IPA, Karlsruhe Institute of Technology (KIT), BRIGHT Testing GmbH, iFAKT GmbH, and Riebesam GmbH & Co. KG, is spearheading efforts to enhance the longevity of electric motors. Traditionally, these motors are shredded and recycled, leading to the destruction of individual components and assemblies.

Funded by the German Federal Ministry for Economic Affairs and Climate Protection, the REASSERT project seeks to develop methods for refurbishing electric motors, allowing for their reuse in vehicles. The drive for sustainability arises from the valuable raw materials, such as copper and rare earth metals like neodymium, contained in electric motors.

See also: Schaeffler AG Secures 420 Million Euro Development Loan from European Investment Bank

As electrification advances, the project aims to establish circular economy strategies, emphasizing “reuse, repair, remanufacture, and raw material recycling” to reduce resource consumption and minimize waste.

The current recycling methods result in shredded and contaminated material that can no longer be effectively used in motors, prompting the project participants to advocate for prioritizing high-quality value preservation strategies over raw material recycling. The goal is to create a closed-loop system, minimizing dependence on raw material imports and reducing the need for extensive raw material extraction.

Julian Große Erdmann, a scientist at the Fraunhofer Institute for Manufacturing Engineering and Automation IPA, underscores the significance of establishing a circular economy. The project defines reuse as the utilization of the entire engine in a second application, repair as the replacement of defective components, and remanufacturing as the removal, cleaning, refurbishing, and reuse of all components.

See also: Schaeffler Boosts Offer for Vitesco Merger, Sets Integration Plans in Motion

To address challenges in disassembling and reusing magnetic materials, particularly rotors with permanent magnets, the team aims to develop non-destructive disassembly methods. An AI decision tool will assist in selecting the optimal value retention strategy, and the acquired knowledge will inform the design of new electric motors. The ultimate objective is to create a prototype motor for the circular economy, emphasizing easy dismantling and application of the identified value retention strategies.