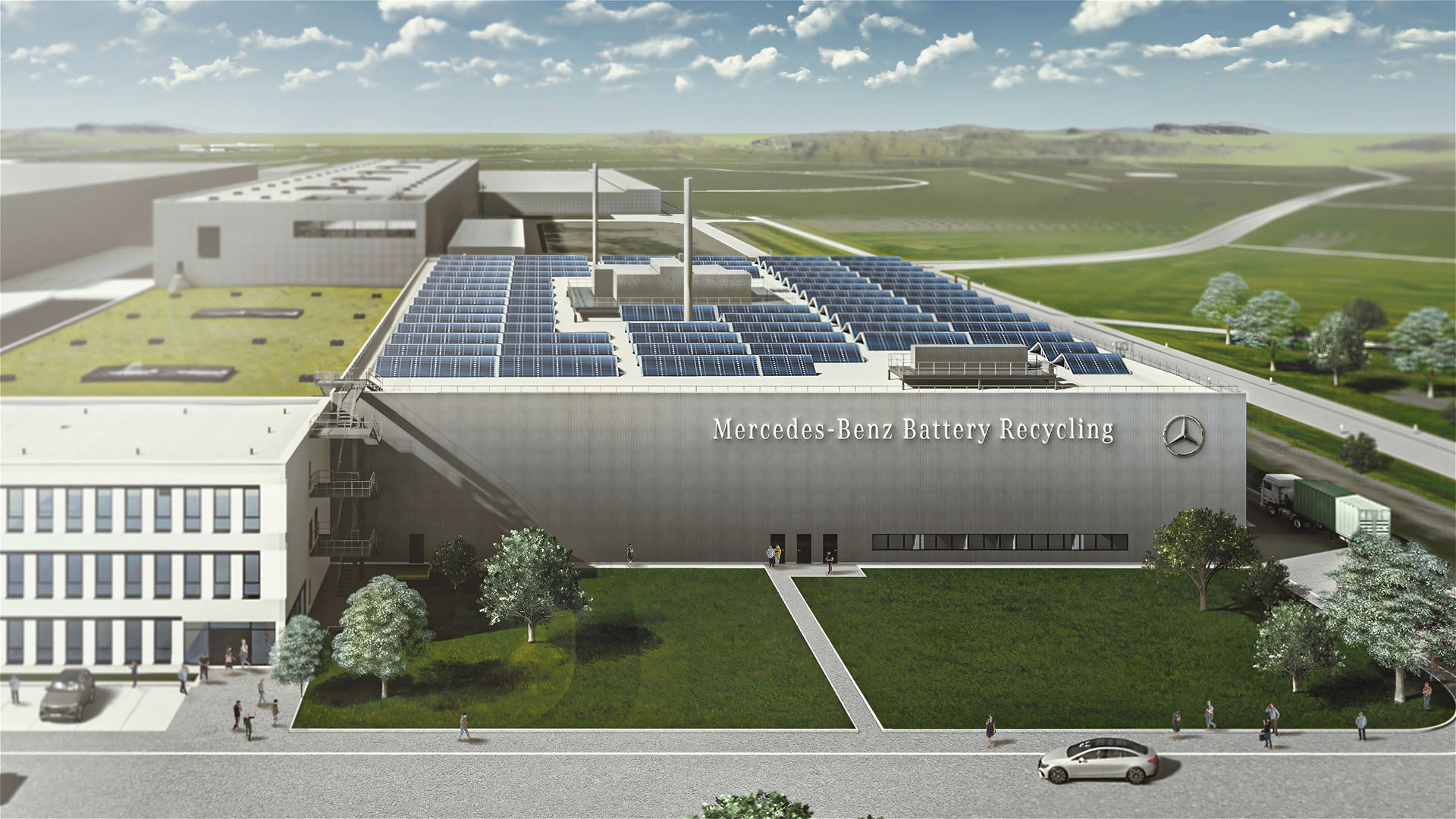

Mercedes-Benz has initiated the construction of a new battery recycling plant in Kuppenheim, Germany. The primary objective of the facility is to minimize resource consumption and promote a closed-loop recycling process for battery raw materials. The first phase of the project, which entails the mechanical dismantling of electric vehicle batteries, will commence towards the end of this year.

The construction of this carbon-neutral plant is set to cost Mercedes-Benz a double-digit million Euro amount. The pilot plant is expected to have an annual capacity of 2,500 metric tonnes.

See also: Mercedes Benz expects to have factories producing exclusively electric vehicles after 2025

The reclaimed materials will be utilized in the recycling loop to create over 50,000 battery modules for new Mercedes-Benz models. The production capacity could be expanded in the medium to long term, based on the findings of the pilot plant. In addition, batteries that are no longer useful in vehicles can still be employed in second-life storage systems.

This investment bolsters the position of the Kuppenheim factory in the global Mercedes-Benz production network. Jörg Burzer, a member of Mercedes-Benz Group AG’s board of management for Production and Supply Chain Management, states that “the foundation represents a crucial milestone towards closing the material cycle for Mercedes-Benz batteries.” He further adds that the technology used is innovative and allows the incorporation of valuable raw materials into new Mercedes-EQ vehicles, resulting in a recycling rate exceeding 96%.

Burzer emphasizes that Mercedes-Benz is continuously expanding its expertise in the battery value chain and is taking a significant step in its strategy towards “Electric Only.” By collaborating with industrial and scientific partners, the company is showcasing the potential of Baden-Württemberg and Germany to innovate in the field of sustainable electromobility.