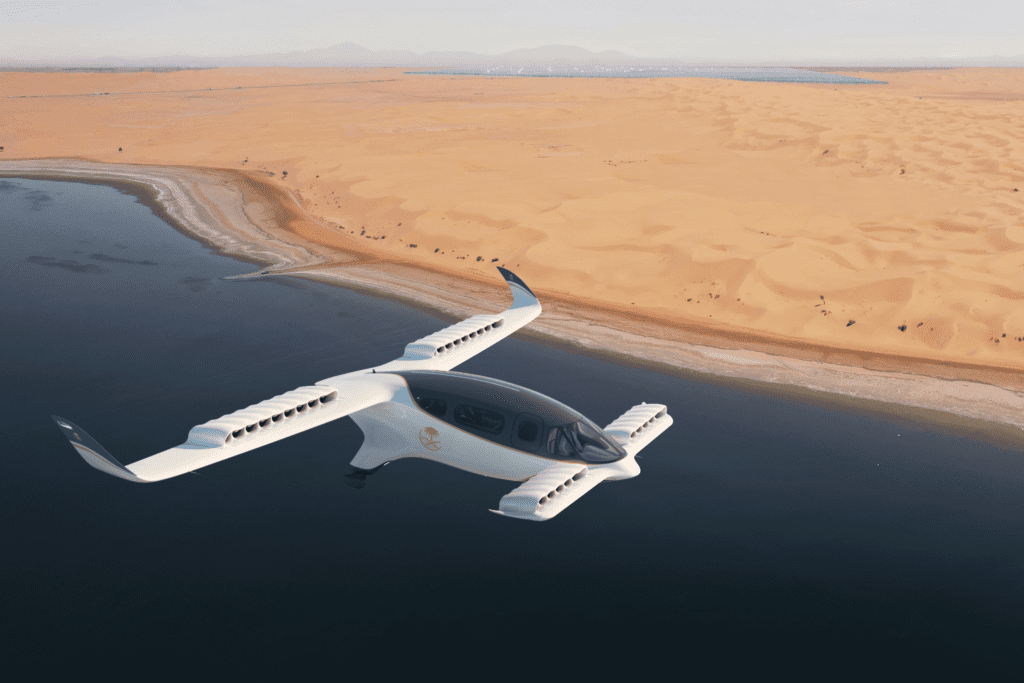

Lilium, a German air taxi developer, announced on Tuesday that it is actively seeking new funding as it accelerates its battery-cell production. The company is competing in a crowded market for electric Vertical Take-Off and Landing (eVTOL) vehicles, hoping to replace road trips or short hops by aircraft or helicopters.

Lilium’s innovative design includes a system of tilting electric turbofans embedded in the wings, which it claims will be quieter than open rotors from rivals. The company plans a cruise speed of 250 km or 155 miles per hour, making it an attractive option for those looking for faster and more efficient travel.

However, Lilium has faced criticism over its battery technology, which requires more power compared to other eVTOL projects. The company has defended its technology, stating that independent tests have shown that its cell technology is on track to deliver the energy, power, and charging cycles it requires.

See also: Lilium Air Mobility targets the production of 400 electric flying taxis per year

“In Lilium, we haven’t only taken something that more or less existed like a big drone or helicopter type of design. You can make your engine become a lifting device, not only a fast device. If somebody said how do you design an unconstrained aircraft, it would look like that. Nothing else moves and it’s all in the software,” said Lilium’s CEO Klaus Roewe in a recent interview.

Lilium’s design is radical and may face challenges in execution, according to updated research from two academics who had previously questioned the company’s battery plans. Nonetheless, Lilium is confident in its approach and is initially targeting contracts with large corporations and private individuals.

Despite the challenges of securing certification and funding innovations such as batteries, Lilium remains optimistic about its future in the eVTOL market. “Complexity should not be in the physical parts but should always be in the software part, because that’s the one you can change the fastest,” said Roewe.