Li-Cycle, the battery recycling company, has officially inaugurated its inaugural European battery recycling facility in Magdeburg. This milestone follows the commencement of trial operations for the facility’s first processing line back in August. At the heart of Li-Cycle’s operations in Magdeburg lies its patented third-generation Spoke technology, a breakthrough innovation capable of directly processing all lithium-ion battery waste, including complete battery packs sourced from electric vehicles, without the need for discharging, dismantling, or thermal processes.

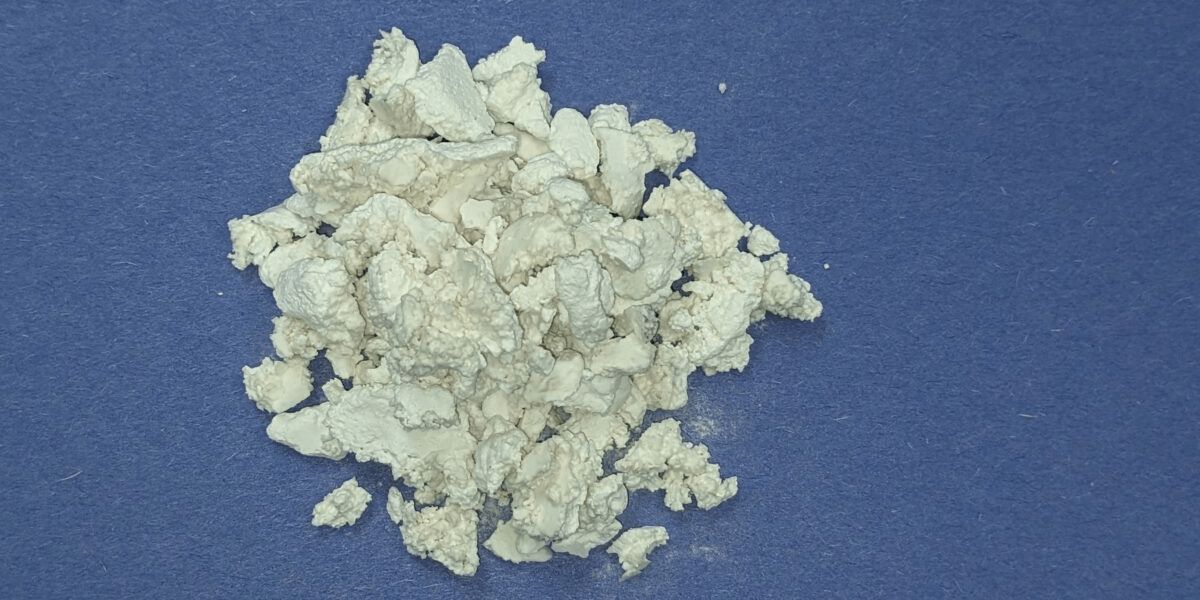

The primary output of this innovative recycling process is referred to as ‘black mass,’ a material rich in valuable battery components like lithium, nickel, and cobalt. The recently opened processing line in Magdeburg boasts the capability to recycle an impressive 10,000 tonnes of battery material annually, producing this valuable black mass. Plans are underway to introduce a second main line, also with a capacity of 10,000 tonnes, later this year. Additionally, Li-Cycle envisions expanding its capacity to a total of 30,000 tonnes in the near future.

One of the inaugural industrial partners for Li-Cycle’s Magdeburg plant is Kion, a prominent intralogistics group. Kion reports that its batteries are currently being recycled by Li-Cycle in Magdeburg. In an ambitious endeavor, Kion aims to divert 5,000 tonnes of end-of-life lithium-ion batteries to Li-Cycle by 2030, equivalent to approximately 15,000 large lithium-ion batteries, commonly found in forklift trucks.

Li-Cycle’s aspirations extend beyond Magdeburg. The US-based company is planning to establish additional European “spokes” in France and Norway, with the overarching goal of achieving a global processing capacity exceeding 100,000 tonnes of lithium-ion battery material annually. The collected black mass will be processed in Li-Cycle’s hub plants. The company’s inaugural hub plant is scheduled to commence operations later this year in Rochester, New York, boasting the capacity to process up to 35,000 tonnes of black mass annually.

Furthermore, Li-Cycle has ambitious plans for a second hub in Europe, collaborating with Glencore to repurpose a portion of Glencore’s existing metallurgical complex on the Italian Mediterranean island of Sardinia. Phase 1 of the Portovesme Hub is expected to initiate black mass processing in the first half of 2024, resulting in the production of lithium carbonate, nickel, and cobalt. Li-Cycle envisions that the full development of the Portovesme Hub in phase 2 will establish one of Europe’s largest sources of sustainable recycled battery materials.