Addionics, an Israeli battery technology company, announced plans on Monday to construct a $400 million U.S. factory dedicated to producing copper anodes for electric vehicle batteries. The facility is slated to commence operations in 2027 with the goal of supplying enough anodes for approximately 1 million EVs annually.

The manufacturing plant will be developed in three phases, with the first phase requiring an investment of $120 million. Addionics CEO Moshiel Biton revealed to Reuters that the company is currently in the process of conducting due diligence for up to $50 million in grants under the U.S. Inflation Reduction Act, primarily for the initial phase.

See also: Addionics Launches New Smart 3D Electrode Pilot Line for Electric Vehicle Batteries

The U.S. Inflation Reduction Act (IRA) offers grants for manufacturing plants and subsidies for EV purchases, provided that the vehicle’s final assembly takes place in North America and at least half of the value of the vehicle’s battery components is domestically manufactured. This stipulation has led to a wave of announcements regarding new plants.

In an online interview, Biton stated that Addionics is considering two potential sites for the factory, which will rely entirely on recycled copper. While he declined to disclose specific automaker partners, Biton mentioned that the company has received letters of intent from several automakers with assembly plants in the United States.

See also: Israel Aims for 30% Electric Vehicle Market Share by 2030, Posing Grid Expansion Challenge

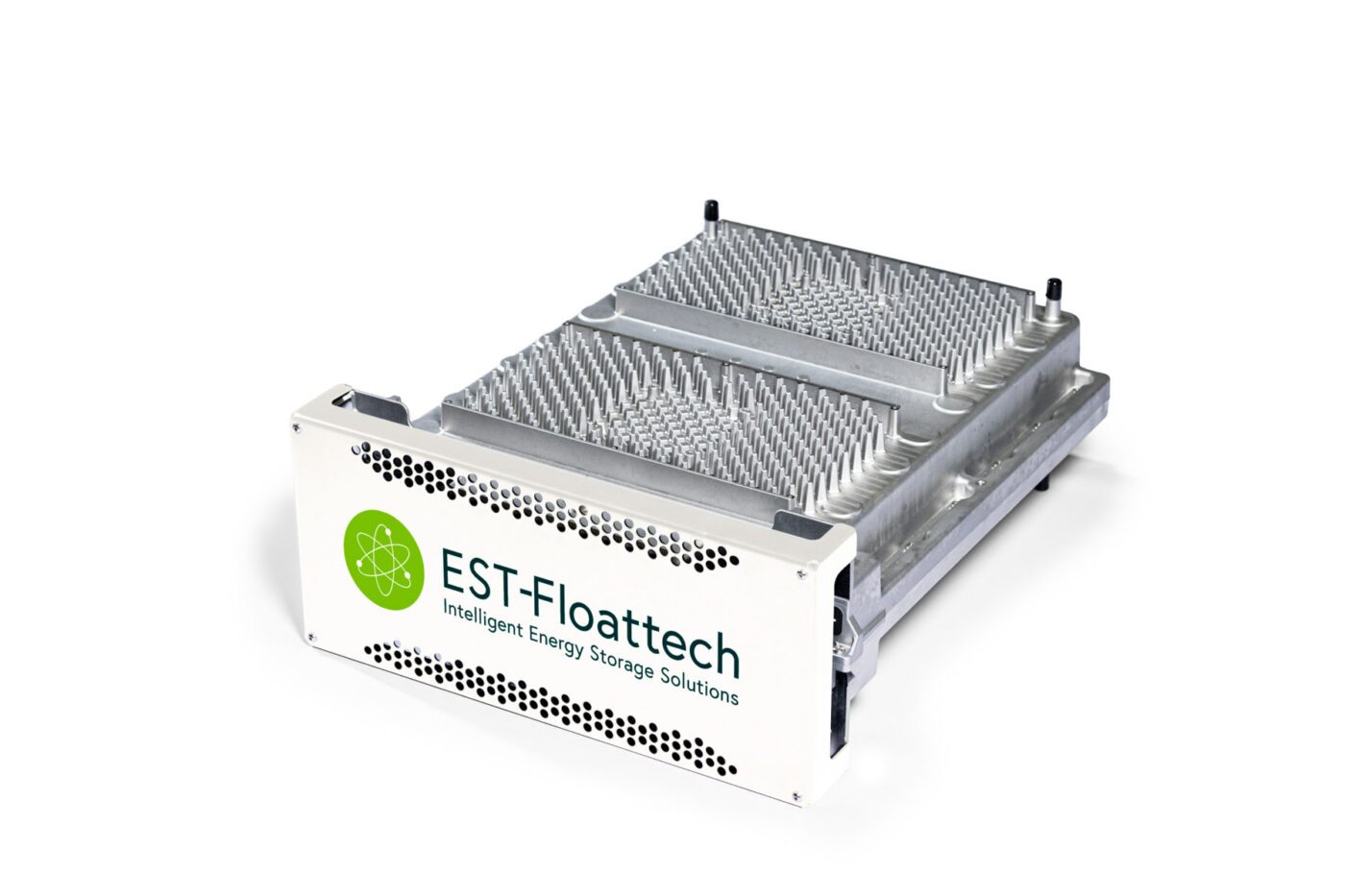

Addionics specializes in porous, three-dimensional copper and aluminum electrode battery materials, which exhibit a delicate, sheer appearance akin to silk scarves when viewed in the light. These materials require significantly less material, including 60% less copper, compared to conventional electrodes. The company asserts that its electrodes enable faster charging, extend EV range by 30%, and could potentially save automakers up to $7.50 per kilowatt-hour.

As traditional automakers race to develop more affordable EVs to drive widespread adoption, Biton emphasized the strong demand for Addionics’ product in the U.S. market, where current production capacity is limited.