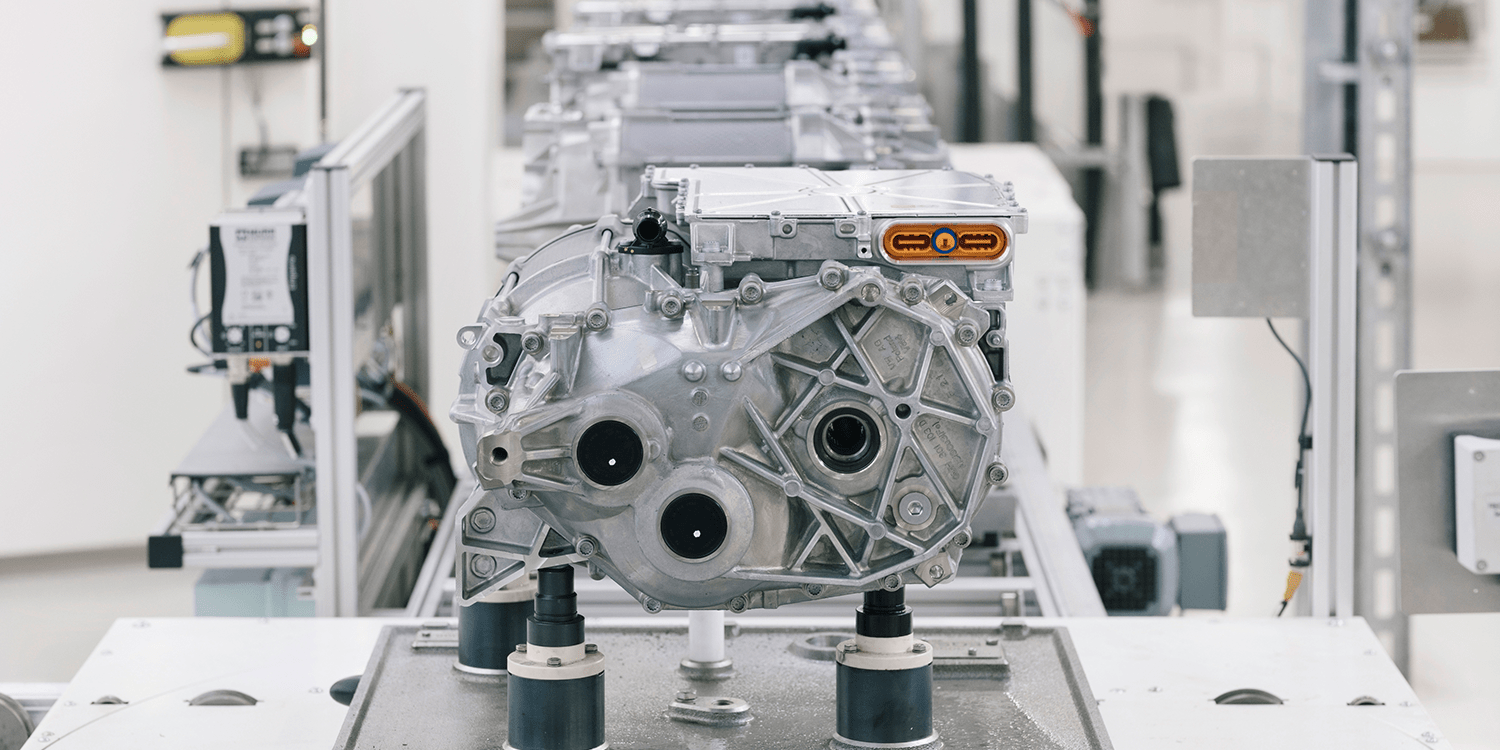

Spain’s Mondragon University has launched a European research and development project called HEFT, aimed at developing cost-effective and efficient permanent magnet electric drive systems with higher power density for the mass production of next-generation electric vehicles. The project, funded by the European Commission, is worth four million euros and will involve eight partners from Belgium, Italy, Slovenia, Spain, and the UK. GKN Automotive will join as an industrial partner to cover the manufacturing process and assembly, ensuring that the final design of the electric drive system meets the industry’s needs and requirements. Other members of the consortium include Magneti Ljubljana, Vyncolit, Ikerlan, and the universities of Nottingham, Bologna, and Leuven.

To align the project with broader resource efforts, HEFT will cooperate with the European Raw Materials Alliance (ERMA) “action plan towards a circular economy market of rare earth permanent magnets”. Once the automotive drive solutions have been worked out, the organizers intend to set up workshops to increase the adoption of its solutions.

See also: KIT’s Groundbreaking Room Temperature Process Recovers Up to 70% Lithium from Used Batteries

The HEFT Project Coordinator and Head of Electric Machines and Drives research group at Mondragon University, Javier Poza, stated that “The HEFT project will allow European companies, research institutions, and universities to successfully position themselves in the market, improving their capabilities and know-how in highly efficient and cost-effective eMotor design and manufacturing. It will also promote new job opportunities linked to magnet recycling and circular economy for rare earth-based magnets.”

Aitor Tovar, Senior Global Manager eMotor Development at GKN Automotive, explains that “The HEFT project is an exciting opportunity to develop the next-generation of eMotors that will be more sustainable and efficient, while costing less to manufacture. Minimising the environmental impact of manufacturing, particularly through a reduction in the use of rare earth critical raw materials, is an essential consideration in the development of future products, so the implementation of a circular economy strategy is another key motivation in our participation in this project.

See also: Stellantis targets the minimum percentage of recycled materials in its vehicles to be 35%

The HEFT project is a promising development in the field of electric vehicles, which will contribute significantly to reducing the environmental impact of manufacturing and promoting a circular economy strategy.