At the Battery Show Europe, three prominent German companies, Dürr, Grob, and Manz, have showcased their collaborative concept for a state-of-the-art lithium-ion battery production facility. This initiative marks a significant step in their joint project aimed at offering comprehensive battery production systems.

The partnership, established in 2022, represents the first European cooperation in lithium-ion battery production technology. The goal is to position themselves as a leading European supplier of complete battery production systems. The trio is making their debut joint appearance at this week’s Battery Show Europe in Stuttgart, focusing on their innovative concept factory.

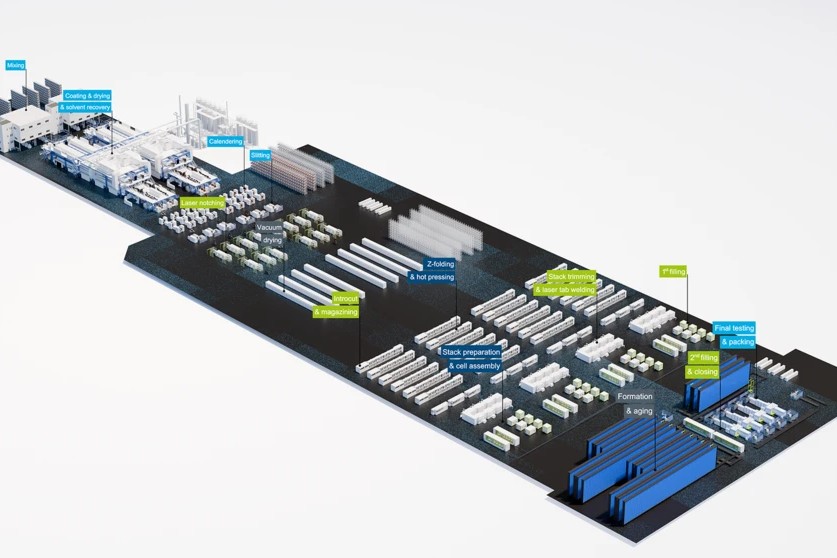

Pooling their expertise, Dürr, Grob, and Manz boast the majority of the required machinery and system technology for the entire battery production process, from electrode production to cell assembly, module production, and pack assembly. The collaboration capitalizes on the combined skills and resources of the three German firms.

Efficiency has been a key driver from the project’s inception, with Dürr emphasizing the importance of “above-average process efficiency of the system.” Technical and digital interfaces between the partners’ trades have played a central role in achieving this efficiency. Dürr’s subsidiary iTAC, specializing in process digitalization, is contributing its MES/MOM solution to enable end-to-end display and control of all production steps in battery production. This ensures high overall system efficiency and lower operating costs, allowing for a smaller footprint and reduced energy requirements.

In addition to cutting-edge plant technology, the three partners offer complete project management services, ensuring smooth implementation according to established project management standards. They emphasize, “Everything from a single source means that Dürr, Grob, and Manz offer smooth implementation in accordance with proven project management standards. In the background, the companies have an extensive network of suppliers.” The first customer project, comprising a system for electrode production and battery cell assembly, is currently underway.