China’s lithium iron phosphate (LFP) battery industry is witnessing a rebound as demand picks up and major manufacturers secure new orders, following a period of price declines that impacted profitability.

Several LFP producers have reported an increase in capacity utilization, with some running at full production to meet rising market demand, according to a report from Securities Times. “Mainstream LFP makers are now generally seeing an increase in capacity utilization, especially with strong demand for high-end products,” the publication quoted a lithium battery materials industry insider as saying.

See also: China Dominates Global EV Battery Supply Chain, Study Finds

In recent months, Jiangsu Lopal Tech has secured long-term contracts with Blue Oval and CATL (SHE: 300750), along with additional orders from LG Energy Solution, the report noted. Meanwhile, Fulin Precision signed an agreement with CATL in August 2024 to supply at least 140,000 tons of LFP per year from 2025 to 2027.

Other LFP manufacturers, including Hunan Yuneng New Energy and Hubei Wanrun New Energy, have also reported strong production and sales since the fourth quarter. Shenzhen Dynanonic stated that multiple production sites continued operations through the Chinese New Year holiday to fulfill customer deliveries.

See also: China Proposes Export Restrictions on Battery and Metal Processing Technologies

With demand improving, some lithium producers have begun adjusting prices. Hunan Yuneng said in mid-January that it had been in discussions with customers regarding price increases, with some already agreeing to the adjustments, according to the Securities Times report.

“Significantly rising market demand and product technology iterations are the two main reasons for the recent price hike of LFP,” said Zhai Linlin, an LFP analyst at market research firm OilChem, as cited by the publication. Zhai added that the cost-effectiveness of LFP batteries has made them the dominant choice in China’s power battery sector, further driving manufacturers to enhance research and development.

See also: TrendForce Reports: China’s Oversupply of Lithium Carbonate Depresses Battery Cell Prices

The shift in market conditions marks a turnaround for many LFP manufacturers, who faced financial pressure in recent years. “In the past two years, most LFP manufacturers were in a loss-making state, and they are now eager to turn around the loss,” Securities Times quoted Shanghai Iccsino Data senior researcher Zhang Jinhui as saying. Zhang added that instances of manufacturers selling at a loss have significantly declined, and there is now greater confidence in maintaining price stability.

Lithium, a crucial raw material in battery production, accounts for a significant portion of electric vehicle (EV) costs. The Chinese lithium market experienced extreme price volatility in 2022, with battery-grade lithium carbonate peaking at RMB 590,000 ($81,170) per ton in November, up approximately 14 times from June 2020. Prices later declined sharply, and battery-grade lithium carbonate currently trades below RMB 80,000 per ton in China.

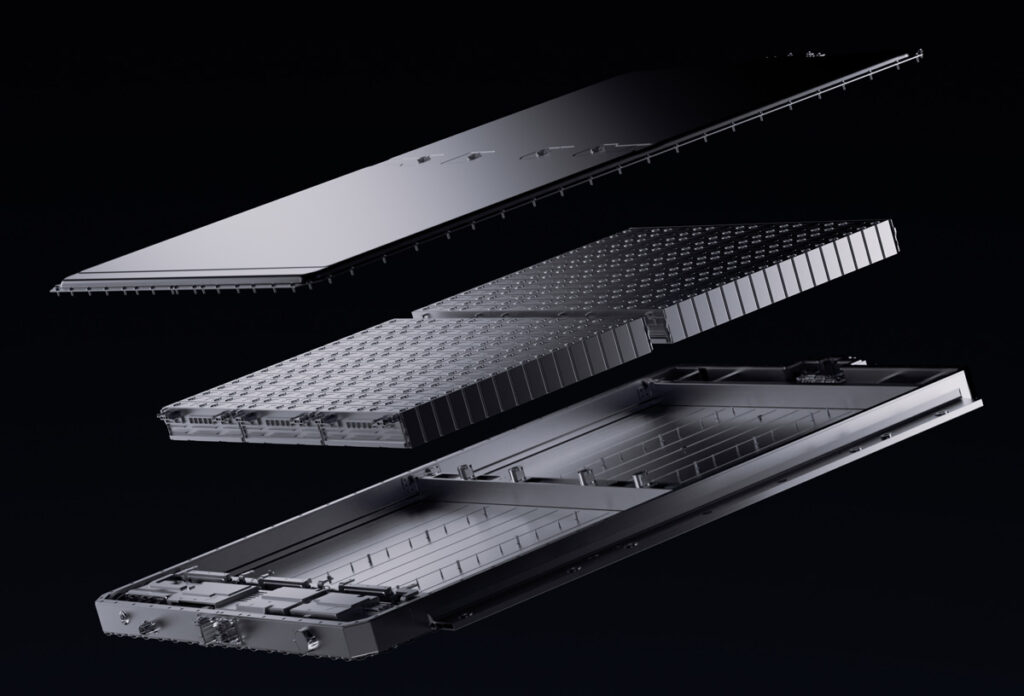

See also: CATL Unveils Shenxing Plus LFP Battery with 1,000 Kilometre Range at Auto China

With demand stabilizing and production capacity increasing, industry analysts anticipate further adjustments in the LFP sector as manufacturers seek to balance supply, pricing, and profitability.