Altilium Metals has recently shared new details about its planned EV battery recycling plant in Teesside, Northeast England. The company’s latest goal is to provide about 20% of the UK’s cathode active materials (CAM) demand by 2030. This comes as Altilium received approval from the UK Environment Agency to recycle ‘black mass’ from EV batteries on a large scale.

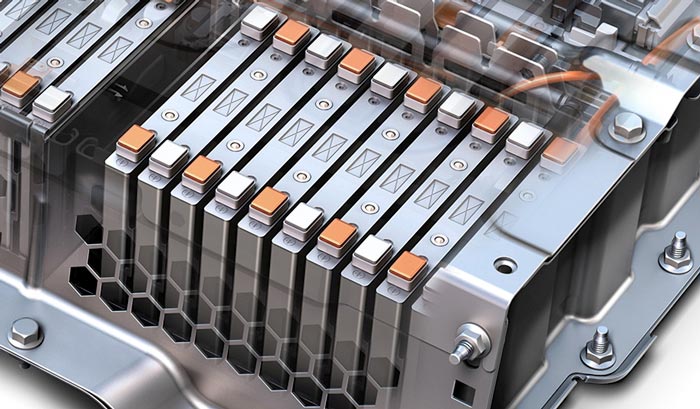

The recycling plant in Teesside is expected to produce 30,000 metric tons of CAM per year, recovered from end-of-life batteries from electric vehicles and waste from battery factories. This will account for 20% of the estimated 150,000 metric tons of CAM that will be needed annually in 2030 for UK-made e-vehicles. Altilium Metals cites a processing capacity in the order of 50,000 tons of ‘black mass’, with various battery chemistries such as LFP, NMC, and LCO capable of being processed.

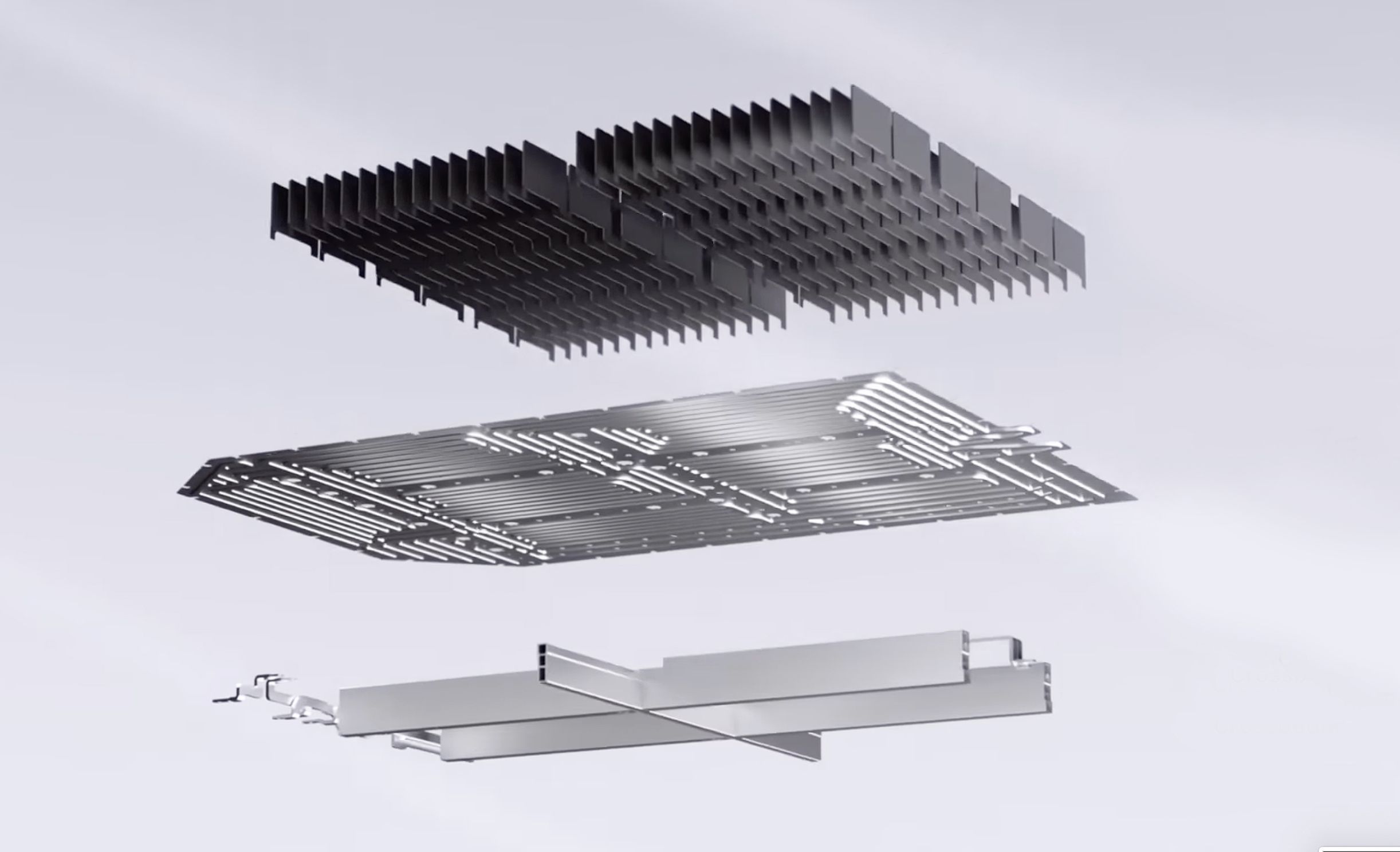

Moreover, the company plans to build a chemical plant in Teesside that will produce 95,000 metric tons of battery precursors like lithium carbonate and nickel sulfate. While Altilium Metals has not specified the exact location of the facilities or the startup date, an earlier report mentioned that the company would receive £3 million in funding from the British government and create 200 full-time jobs.

Altilium’s move towards EV battery recycling is a significant step for the UK, which is still lagging behind in terms of EV battery production. Britishvolt’s recent bankruptcy and the uncertain future of the gigafactory project have highlighted the need for investment in EV battery production and recycling. While Green Lithium also plans to build a lithium refinery in Teesside, the UK still lacks customers. The only cell production project that is ready for the automotive industry in the UK is that of Envision AESC in the vicinity of the Nissan plant in Sunderland.

Altilium Metals has been making significant progress in EV battery recycling, having opened an electric vehicle battery technology center in Devon last year. The company also owns a hydrometallurgical recycling facility on the largest copper mine waste resource in Eastern Europe and is currently developing the facility to recycle battery waste from 24,000 electric vehicles per year, starting in late 2023.

Altilium’s commitment to EV battery recycling is an essential step towards a more sustainable future, and the company’s innovative approach to recycling and producing battery precursors will undoubtedly have a positive impact on the environment. With the UK government’s support and the company’s focus on scalability and product quality, Altilium Metals could become a leading player in the UK’s EV battery recycling market.