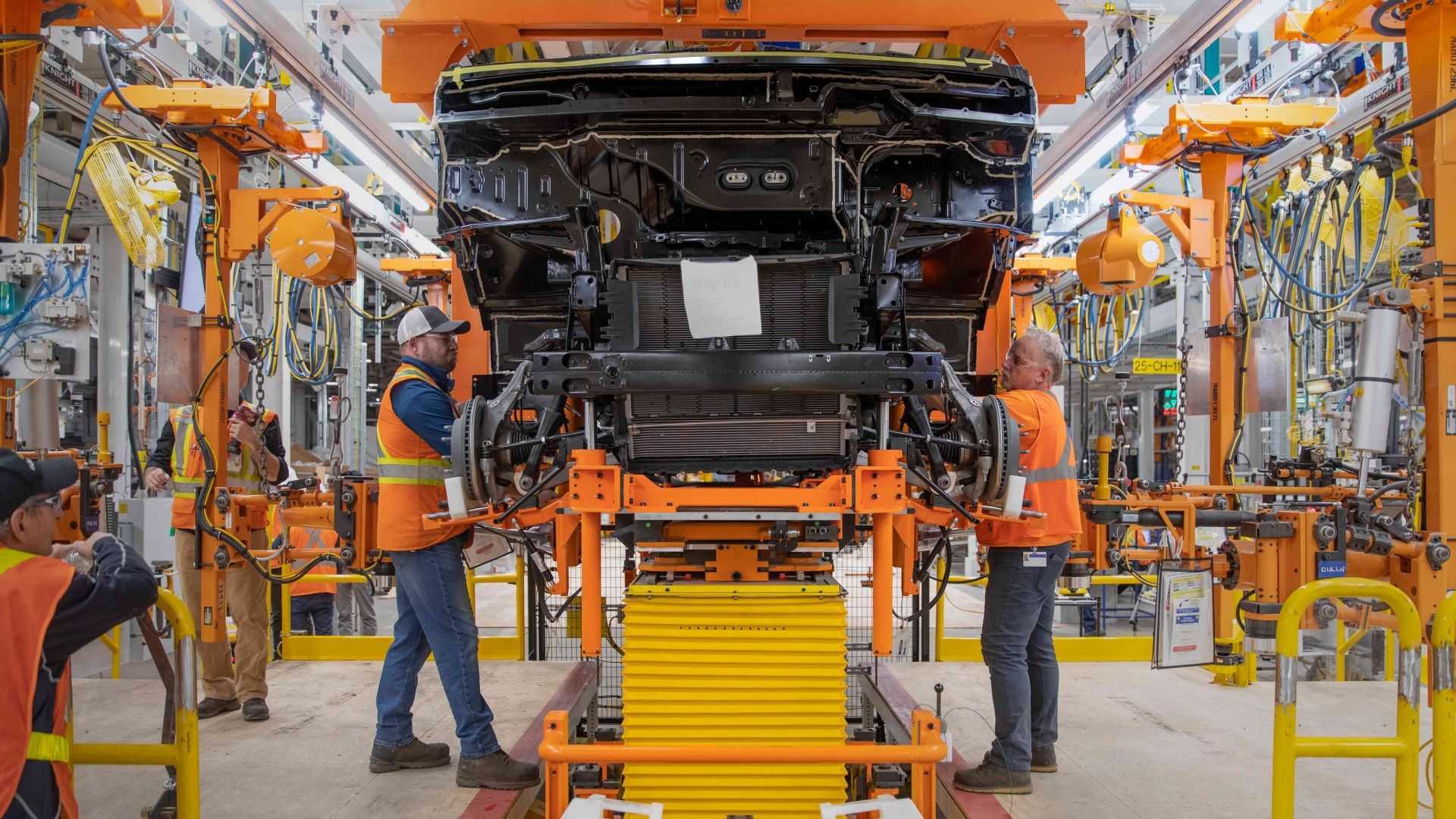

General Motors’ CAMI Assembly plant in Ingersoll, Ontario has faced an unexpected shutdown, leaving its workforce idle for the month. The closure is reportedly due to a shortage of batteries, according to the Unifor union representing the workers, as reported by The London Free Press via Electrek. The facility is responsible for producing the BrightDrop Zevo 600 and Zevo 400 electric delivery vans, which rely on General Motors’ Ultium battery.

The high demand for the Ultium battery in other GM electric vehicles has led the automaker to temporarily close the CAMI Assembly plant. Despite strong sales of the BrightDrop vans, production will be limited due to the battery shortage. Mike Van Boekel, chairperson of Unifor Local 88, stated that the battery scarcity, resulting from a bottleneck in raw materials, has affected all GM plants. Van Boekel mentioned that although sales are thriving and demand is high, the company simply does not have enough batteries to meet production needs.

CAMI Assembly currently holds approximately four years’ worth of orders, but addressing the battery shortage will take time. Van Boekel noted that GM is actively working on producing more batteries but emphasized that it is a process that cannot be expedited.

The Ingersoll facility employs around 1,500 individuals. Prior to the shutdown, workers were on rotating shifts, working two weeks on and four weeks off, to ensure continuous employment. During the off weeks, employees received 60 percent of their pay from employment insurance benefits and a supplementary amount.

Understandably, the decision to close the plant for the remainder of the month has created frustration among the staff. Van Boekel expressed workers’ desires to return to work and earn wages, especially as costs continue to rise. The employees are expected to resume their duties on July 31.

Currently, General Motors exclusively manufactures Ultium batteries at the Ultium Cells plant in Lordstown, Ohio. However, the company has plans to establish a second plant in Tennessee by 2024 and a third in Michigan by 2025.

Sources familiar with CAMI Assembly have reported that GM Canada is constructing a 400,000-square-foot addition to the Ingersoll plant. This expansion will enable the carmaker to assemble its own batteries for the BrightDrop vans. Analysts predict that GM will sell over 70,000 electric vehicles this year, with the majority consisting of the Bolt EV and EUV models, which do not utilize Ultium batteries.

The production of electric vehicle batteries relies on essential metals like lithium, cobalt, and nickel. These metals are primarily sourced from overseas, with China being a major producer. There are growing concerns globally regarding potential shortages of nickel, lithium, graphite, and cobalt, which may exacerbate the existing battery supply issues.