Caresoft Global Technologies, an engineering company based in Michigan specializing in digital and physical benchmarking and cost reductions, predicts that Tesla’s assembly times will decrease by 25% in its upcoming model upgrades. The company believes that Tesla will continue to enhance its manufacturing process, resulting in improved efficiency and reduced production costs.

In a recent forecast, Caresoft Global Technologies also projected a 30% reduction in Tesla’s capital investments in plants. Additionally, the company anticipates a significant decrease of 30% in the floor space of future Tesla factories, while simultaneously enhancing the efficiency of its paint shops.

See also: Tesla’s Project Highland Model 3 Revamp Set to Amaze Customers

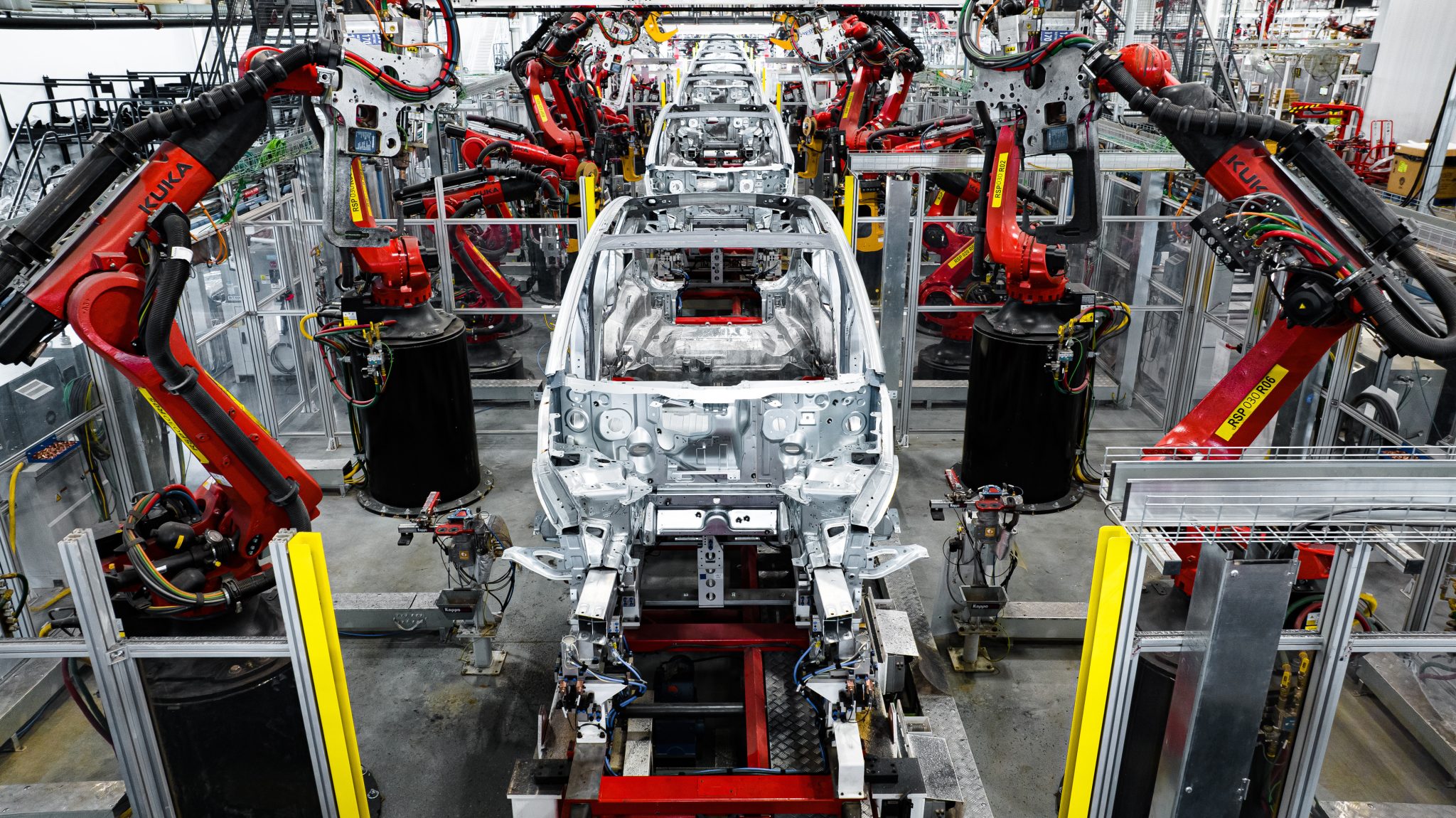

Caresoft CEO Mathew Vachaparampil highlighted Tesla’s corporate culture, stating, “Tesla has a consistent drive for radical improvements from year to year, even within the same vehicle design.” This commitment to innovation and progress has been evident in Tesla’s continuous efforts to streamline production processes. For instance, Tesla has successfully reduced the number of parts required for Model 3 and Model Y production through the implementation of casting machines.

Looking ahead, Tesla’s next model upgrade, known as Project Highland, is set to introduce a new iteration of the all-electric Model 3 sedan. Recently, a Project Highland Model 3 was spotted in California, providing a glimpse of some anticipated new features, including redesigned headlights and Hardware 4 cameras.

See also: Tesla’s Giga Mexico Facility Set to Begin Car Production as Early as Next Year

Furthermore, Tesla’s plans for the future extend beyond vehicle upgrades. Governor Samuel García Sepúlveda revealed that Tesla Giga Mexico is expected to establish an entirely new production line dedicated to manufacturing the highly anticipated $25,000 compact car. This move indicates Tesla’s determination to develop more efficient production methods, aimed at reducing costs while ramping up overall vehicle production.