Fortum Battery Recycling, a subsidiary of Finnish energy company Fortum, has recently obtained environmental approval under the Federal Immission Control Act to recycle traction batteries from electric vehicles in Kirchardt, a town in southern Germany. The newly opened recycling center in Kirchardt has already begun operations and has the capacity to process over 3,000 tons of batteries per year.

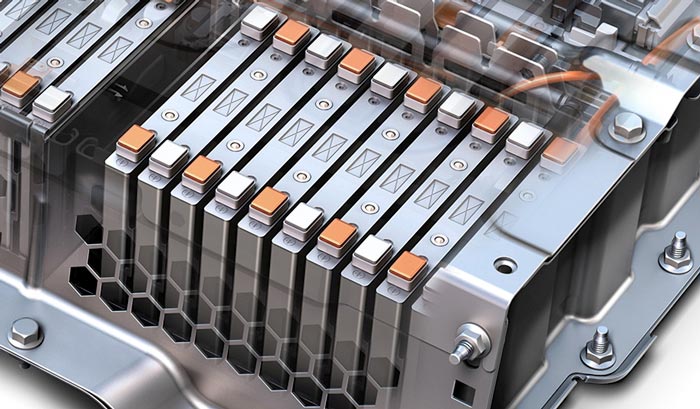

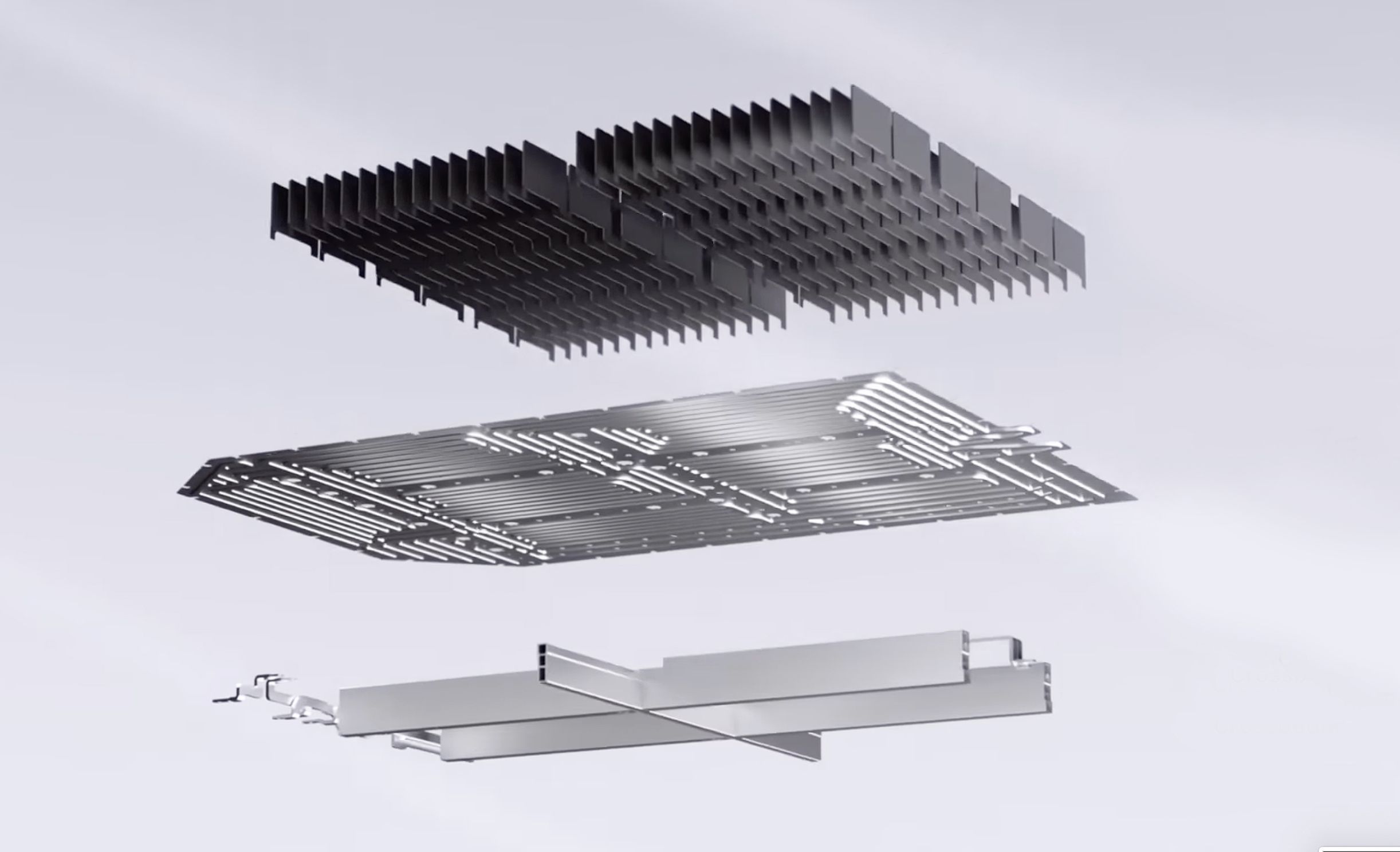

The company uses a combination of mechanical and hydrometallurgical technologies to recycle battery materials, allowing for the recovery of 95% of the valuable metals from the battery’s black mass. The German plant will be linked to Fortum’s hydrometallurgical recycling plant in Harjavalta, Finland, which is set to begin commercial operation in the coming weeks.

See also: Cirba Solutions and General Motors Extend collaboration for recycle electric vehicle battery

The black mass obtained in Germany will be processed at the Harjavalta plant, and the individual battery raw materials will be chemically separated. These raw materials can then be fed back into the battery value chain.

Fortum Battery Recycling’s expansion into Germany provides local manufacturers with a unique opportunity to connect with the fast-growing Finnish sustainable battery raw materials cluster. The company is also exploring further expansion opportunities in other European regions, though plans are not yet public.

See also: BASF and Tenova Collaborate to Develop Sustainable Battery Recycling Process

Frank Stumpf, Operations Director at Fortum Battery Recycling, stated that “Our operations cover all the necessary handling and production steps for the highest recycling rates: pre-treatment services, black mass production and hydrometallurgical recovery of metals.” The move towards electric vehicles will only continue to grow, and companies like Fortum Battery Recycling are taking the necessary steps to ensure that the end-of-life of these vehicles is handled responsibly and sustainably.